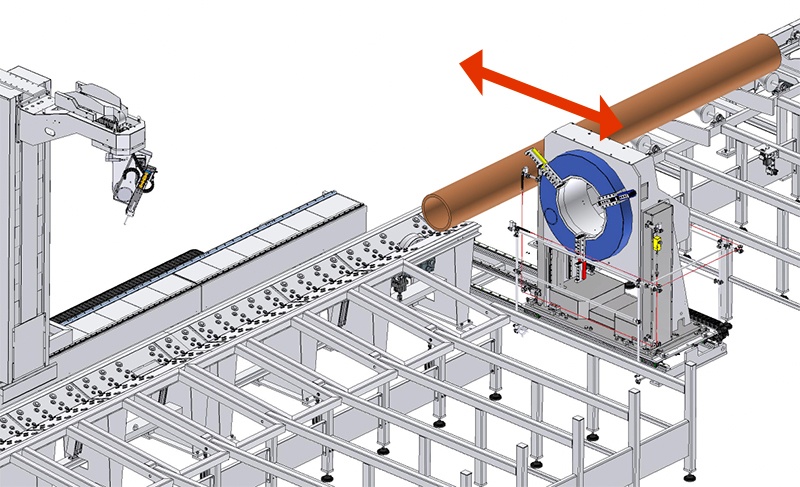

With a laterally movable chuck, MÜLLER OPLADEN revolutionizes the automatic handling of pipes in the manufacturing process: The pipes are made available on a roller table behind the chuck. The chuck moves out of the zone and clears the way to push the pipe onto the cutting roller table. Back in the production position, the chuck picks up the pipe for processing. The finished pipe is removed via a discharge roller table for the following production steps.

This increases the productivity of a system by up to 15%! Since the chuck no longer has to be designed larger than the maximum pipe diameter, the system becomes significantly lighter and cheaper: This innovative chuck solution saves up to 2/3 of the costs!

Existing MO machines can therefore be retrofitted at low cost. Even systems with in-line logistics systems from other manufacturers can now be easily replaced by a powerful MÜLLER OPLADEN tube cutting machine without having to renew the entire logistics.

A real highlight, isn‘t it?