3D coping machine

We at Mueller Opladen offer 3D Coping machines for profile cutting steel round and square shapes. The company is manufacturing and engineering these stationary multiple axis CNC controlled machines for profile cutting since many years.

The factory and office of Mueller Opladen are situated near Leverkusen in de city of Opladen. The company is more than a 100 years old and has experience in manufacturing high quality 3D coping machines for many years. The focus of the company is to deliver the highest quality 3D profiler that is available in the market with a high standard of technology and latest software options.

visit our website www.mueller-opladen.de for the different 3D coping machines we offer for pipe, tube, pressure vessels. Or the coping machines we offer for square shapes like different kinds of beams, girders and U-channels

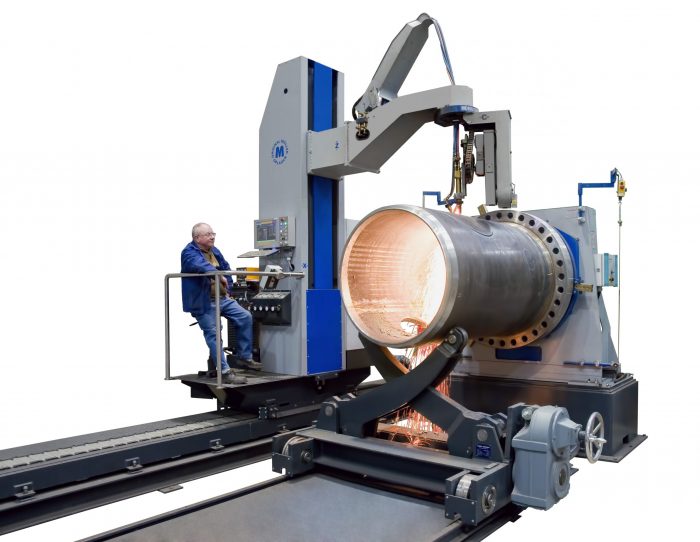

3D pipe coping machine

For 3D pipe coping we are providing a wide spectrum of different stationary CNC controlled machines to the market of pipe fabrication and welding.

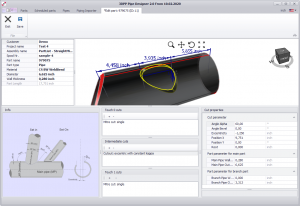

We have the MO-Compact series with 6 CNC axis these series covers pipe diameter up to 36″. This machine is having unique features for providing you the most accurate thermal cutting possibilities because of the 6 axis that are included. the fifth and the sixth axis are needed for adapting on deviations that are encountered by the scanning process before the machine starts cutting. Mueller Opladen is unique worldwide with providing 3D pipe coping machines with a minimum of 6 CNC axis on the machines they manufacture, this is basically the best profile cutting result.

contact us for qoutations on our 3D pipe coping machines on mail@mueller-opladen.de

3D coping

What our machines do is 3D Coping or so-called 3D profiling cutting steel. Most of our solutions are related to 3D coping pipes, tubes or pressure vessels. This means round steel is being pierced and cutted with thermal cutting processes like plasma cutting and oxyfuel cutting. A good example of our 3D coping machines dedicated for round steel is the MO-Compact for pipe diameters up to 36 inch (914 mm) and the MO-Classic for pipe diameters that are bigger than 36″.

Our 3D coping machines for round steel like pipes are always having a minimum of 6 CNC axis when they are manufactured by Mueller Opladen. 4 CNC axis are required to do all 3D coping activities like cutting saddle cuts, miter cuts, rat holes, slots, straight cuts, holes and so one. But, axis number 5 and 6 are needed to keep track on out of roundness in the pipe outer diameter and to adapt on this out of roundness or other deviations in the pipe diameter as for example weld beads or damaged parts. This adaptation feature is called “adaptive control” this means in fact that the means adapts it’s axis and controls to still provide a perfect profile cut as desired to the saved drawing in the CNC software.

Another example of 3D coping machines are can offer you is a machine dedicated for square and rectangular shaped steel, this is the MO-Robo. This means is capable of profile cutting these shapes up to 1200 mm height, this also means it can profile cut H-beams, T-Beams, U-Channels, L-Channels and so on. Visit the website of the MO-Robo for more information, pictures and a video.

3D beam coping machine

Our machines are applicable for 3D cutting steel in different shapes and contours. Mueller Opladen is manufacturing these stationary machines since the 1950s the main focus of the company is offering 3D profile cutting machines for round shapes such as pipes, tubes and pressure vessels.

Other machines we have are designed for 3D profile cutting square shapes such as beams, rectangular pipes, box sections, girders, U-Channels, L-Channels and so on this machine is called the MO-Robo go to the dedicated webpage for more information.

If you require advice or a quotation contact us on mail@mueller-opladen.de

![]()