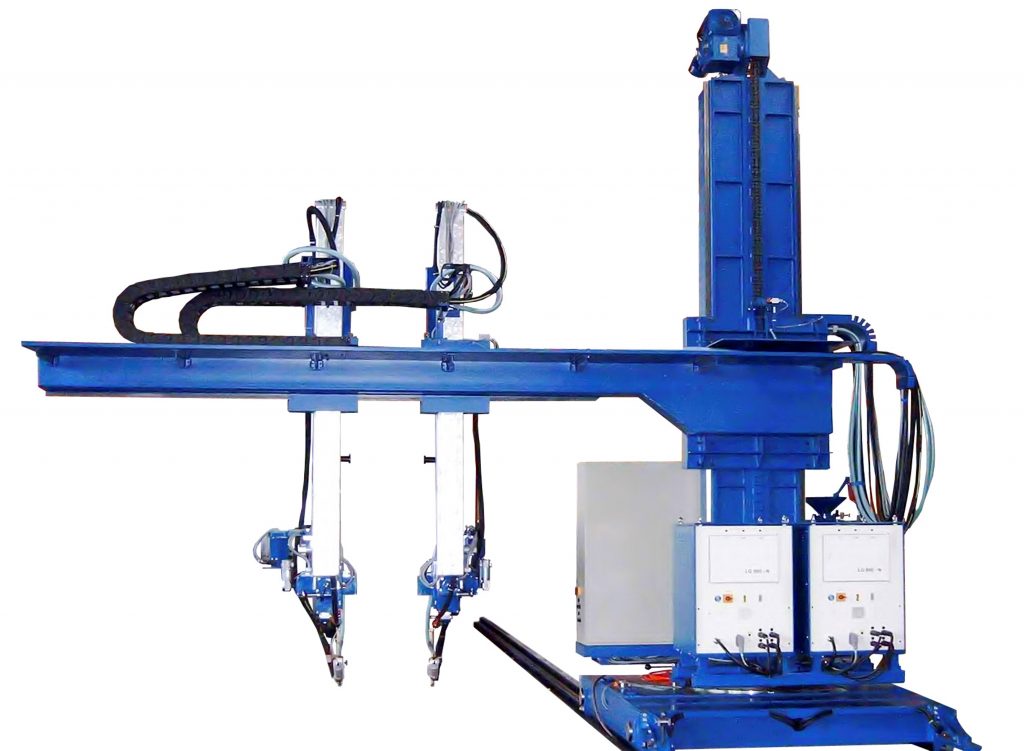

The Column and boom welding machines from Mueller Opladen could be equipped with MIG, MAG, TIG, WIG, SAW or plasma welding processes. The PLC controlled column and boom system that we offer is manufactured from steel profile to make the system robust and reliable for a long-lasting use. The machines are designed for heavy duty industrial use.

The specifications of our Column and boom welding systems are based on the end customers request even the welding process can be choosen from MIG, MAG, SAW, TIG, WIG and plasma welding processes. Standard we offer these welding machines with PLC software from Siemens and on top of the Siemens PLC we created our own operator level dedicated for this welding process.

The welding source we often use from Fronius, Polysoude or EWM based on these specific customer preferences or most suitable power source for the chosen application. Within all our automated welding machines the customer is deciding in the end how the custom based welding solution should look like looking at the welding source brand, welding process, the machine process and operation.

Go to our webpage for more information about our different options within the column and boom welding systems that we engineer and manufacture in our German factory.

For specific welding request you can also email us on mail@mueller-opladen.de and we come back to you shortly.

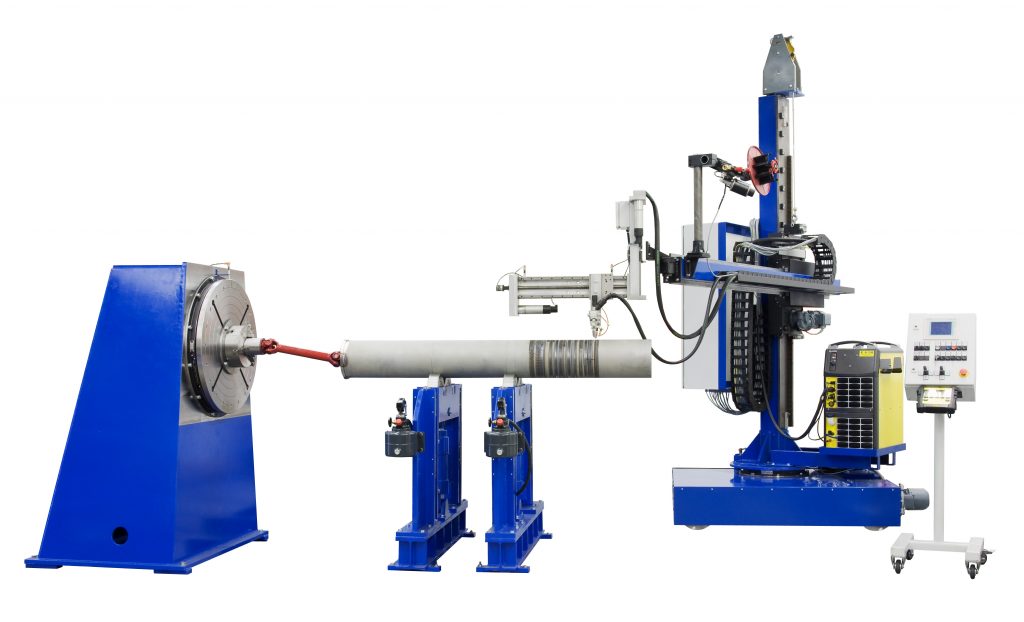

Mueller Opladen is manufacturing automated welding machines since the 1960s, one of the most common machines we sell in the welding segment is the circumferential welding machines for welding round steel objects to eachother. The circumferential welding operation is a process where the parts are clamped in a chuck that rotates during the welding process.

This circumferential welding machine can be combined with a boom welding module to for example create a pipe spool welding machine. The circumferential welding machine has the workpiece mounted on the rotating chuck during the welding. When the spool is rotating the column and boom welding segment of the machine move up and down on the column and change also position on the boom. We focus on engineering and manufacturing robust built and reliable machines with machine parts from trustable proven sources that are built up expertise in their field and offer high-quality parts.

All the column and boom welding machines are equipped with Siemens PLC software with on top of it an operator level built by Mueller Opladen. We also sell the column and boom welding machines as a stand-alone welding machine. The markets that we focus on with this welding solution are the pressure vessel and boiler manufacturing industry, special offshore construction and hydraulic cylinder manufacturing. In fact, these have been markets that we sold these machines to before but there are way more industries and applications that can make use of a column and boom welding machine.

Our column and boom welding machines are designed for heavy-duty industrial use and manufactured in such a way that they are reliable and existing of premium machine parts. These welding machines can be used for multiple purposes, but if we look to the end customers in the welding industry that bought such a column and boom machine from us, we see that most of them are in the manufacturing of vessel, boilers of pressure vessels. That means that you can find these systems in the petrochemical, oil gas and offshore industries.

Yet another market where we have sold quite a few of these C&B welding machines to is the hydraulic cylinder production market.

The end customer could choose which of GMAW, GTAW, SAW, WIG or Plasma welding processes fits best with their application and we could offer this equipment with one of these welding processes based on the customer needs.

The column and boom welding machines can be engineered for butt welding and fillet welding or so-called socket welding applications. contact us for more information and custom made offers.

All our welding machines are equipped with PLC software from Siemens standard.

Contact us on mail@mueller-opladen.de for quotations on column and boom welding machines

Mueller Opladen is manufacturer and engineer from automated welding machines, one type of machines that the company is offering are the Column and boom welding solutions.

Column and boom welding machines can be equipped with SAW single or tandem, MIG/MAG, TIG or PLASMA welding equipment. Depending on the type of column and booms welding manipulator that is used, it can be used for welding structural beam welding as well as welding of pipes, tubes, tanks or pressure vessels. Column and booms specific requirements can be agreed individually.

Columns and booms, ranging from 2 x 2 metres up to 9 x 8 metres for column lift and boom range, are used for the positioning and guidance of welding heads, welding torches and other tools. Columns & booms can thus be combined with positioners and/or roller beds in a variety of applications such as the welding of circumferential or longitudinal welds or build-up welding of alloys on workpieces.

Contact us for your column and boom requirement on mail@mueller-opladen.de and we can advise and qoute you the right solution that fits your welding job!

The columns and booms are designed according to proven engineering principles and manufactured at our Opladen location in Germany in robust construction for applications in rugged welding operations and tank construction.