American concern P1 relies on tube machining Made in Germany

The KansasCity-based US company P1 is investing in a total of 6 pipe processing systems from Müller Opladen this year to make their production more efficient and better.

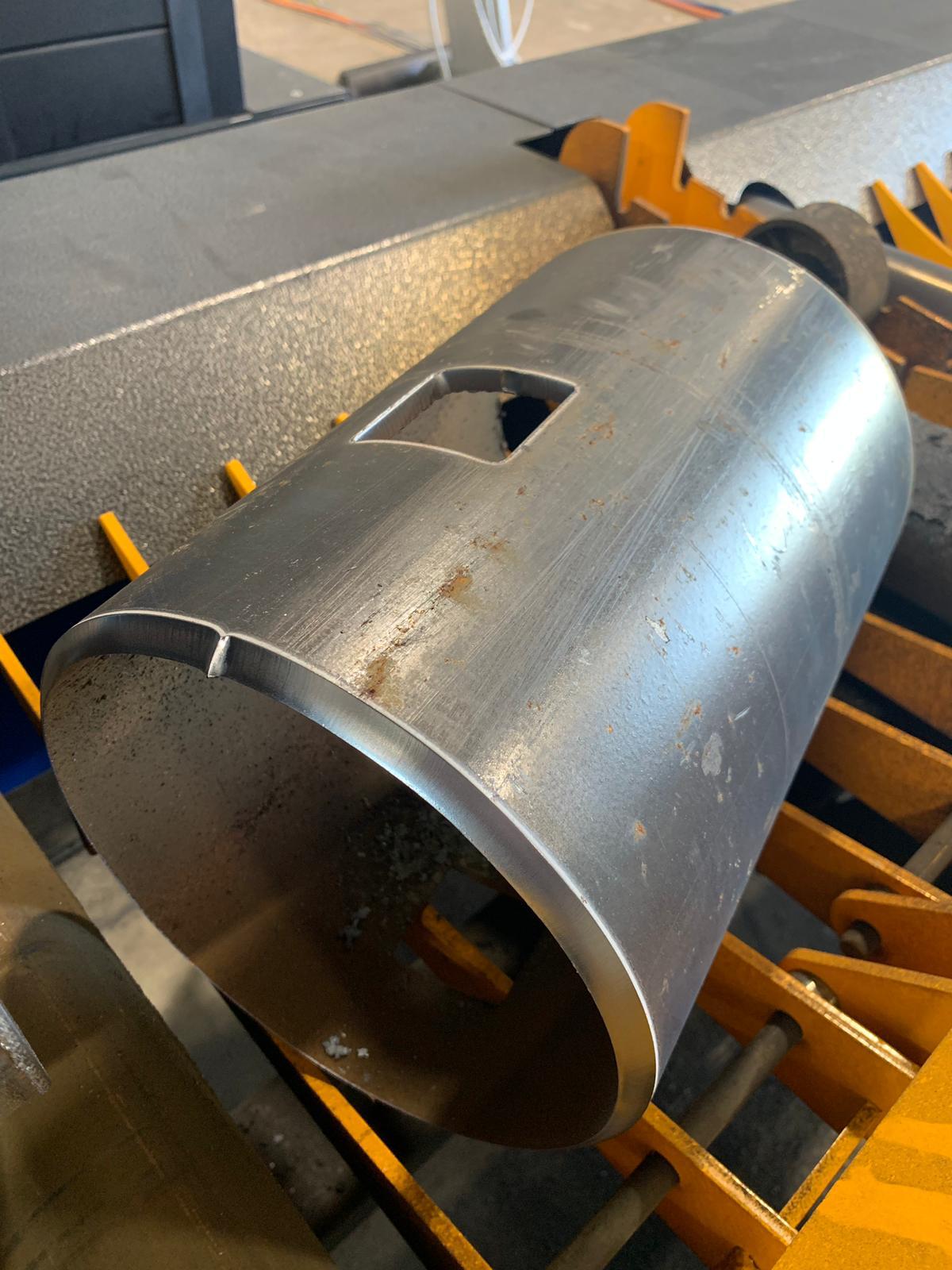

The centerpiece is the MO Compact 900 from Müller Opladen, which is embedded in automated production through the complete tube logistics of the MO subsidiary Watts Mueller (Seattle). "This combination guarantees the highest cutting results and very high productivity," says CEO Ralf Hamacher. "This project impressively demonstrates the competence of our group of companies."

On the MO Compact 900/6 with its 6 CNC axes, round tubes with a maximum diameter of up to 914 mm and lengths of up to 12 m can be machined cleanly. The high-performance MO-CAM software is used to create the cutting data for the production, including the nesting of the pipes in order to save material.

Watts-Mueller logistics enables the automated handling of workpieces. Loading and unloading tables, cutting roller tables and transport systems provide the loading of the 3D pipe cutting system and the removal of the finished pipes to further processing or storage.

The P1 Group offers its customers mechanical, electrical and sanitary services in order to better coordinate and implement construction projects. The group has 6 locations in the US. (www.p1group.com)