Müller Opladen is manufacturing for 3D coping beams a robotic plasma cutting machine that is able to do 3D coping of different kinds of steel beams. Our coping machine is capable of cutting H-Beams, I-Beams and T-Beams and different kinds of steel profiles. The name of this robotic coping machine is the MO ROBO 1200 .

This MO ROBO 1200 machine we are standard offering in a robotic cell with infeed and outfeed conveyor. Our 3D coping robot is hanging in an enclosed robotic cell top down from a gantry. We have a KUKA robot with 6 CNC axis and in the gantry, we have built in another 2 axis to be able to 3D cope different structural steel workpieces with sizes up to 1220 mm.

Our MO ROBO 1200 robot is coping the steel workpieces such as beams or steel profiles with a plasma (high definition) in 3D shapes. We can offer you premium plasma cutting solutions from Hypertherm or Kjellberg contact us for advise.

For us it is important to understand your steel coping request in detail that is why we always after receiving the inquiry with the machine requirements want to talk to you face to face to understand what the dimensions and shapes of the workpieces are but also to understand what Your desired output of the system is and what your budget is and time frame on a plasma coping machine for cutting structural steel workpieces.

Contact us for more information about our coping robot for structural steel on mail@mueller-opladen.de

Müller Opladen is a German company that is into the 3D cutting of steel since the 1950s. Over the years the company sold and installed worldwide many different oxyfuel cutting and plasma cutting machines to 3D cut different steel workpieces. With all the experience, skills and development since the 1950s we are proudly presenting you our state-of-the-art plasma coping robot for cutting structural steel this is the MO ROBO 1200 .

To read more technical information on the machine specification and to see a video of the 3D coping robot that we offer for plasma cutting structural steel visit our webpage dedicated for this robot

With our coping machine for steel beams, we offer a great high performance 3D plasma cutting robot that is able to perform all your different coping shapes that you desire on your steel H-Beams, I-beams or T-beams. We are able to mark the workpieces also with the same plasma unit that we are doing the cutting with. If this kind of marking is not allowed for your customers in the steel construction industry, we can also offer air scribers or thermal ink marking options as well.

In the robotic cell where the 3D plasma coping of the steel is taking place, we are optionally able to put a fume extraction unit in and of course we can offer the complete installation and peripheric when we sell the equipment.

Send us your request for quotation on a coping machine on mail@mueller-opladen.de and we will contact your shortly to discuss further.

We have a solution for coping steel beams, it can be done fast and accuratly with our robotic machine that 3D cuts with a plasma all shapes and contours out of the steel workpiece. The robot has CAD / CAM integration, this allows you to send CAD files with 3D profile cuts on the beams to the robot over a LAN connection from your office computer.

Müller Opladen is engineering and manufacturing company based in Leverkusen with experience and developments since the 1950s in manufacturing thermal cutting machines for 3D cutting steel workpieces.

Our standard robotic machine MO ROBO 1200 for coping structural steel is also able to cut H-Beams, I-Beams and T-beams besides other kinds of steel that are used in the steel construction industry. We aimed and succeeded to manufacture a high-quality robotic cell with infeed and outfeed conveyor for 3D plasma coping steel beams and steel profiles.

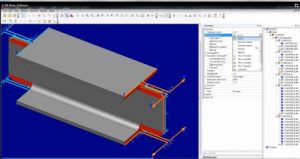

See the pictures below of our standard layout of this robotic coping machine for steel beams and structural steel.

We can infeed and length measure for example a 12-meter-long steel H-Beam on the infeed conveyor, a laser sensor in combination with rolling disk measures and clamps the steel beam on the right length and position with a pneumatic clamping on this conveyor . In this way the beam is in the right position in the robotic cell. Than the coping robot can start doing the probing by touch sensing the beam to gather data about the H-beam and any deviations on the dimensions that there might be. After having completely touched-sensed the H-Beam the robot can start doing the profile cutting or so-called coping based the shapes and dimensions from the CAD file data that has been send to the machine over a LAN connection from the office.

To get an impression how this complete process looks like in operation please watch the video of the MO ROBO 1200 that we have on our website.

Since the start of this coping robot MO ROBO 1200 we cooperated with the premium robotic brand Kuka to offer a reliable and accurate robotic machine in our production line, together with Kuka we have been able to reach our high set standard on accuracy and reliability in this machine that we wanted to reach.

Contact us for your inquiry or quotation on this coping robot on mail@mueller-opladen.de

With our robotic plasma cutting machine we are providing a perfect beam coping machine to do profile coping 3D shapes. Our machine for beam coping is more a production line for fast processing beam coping activities because it has a length measuring infeed conveyor to feed the steel beams in to the robotic cell and an outfeed conveyor to transfer the 3D cutted parts out of the robotic cell.

In the robotic cell we have a coping robot hanging top down from a large gantry, this robotic cell is a completely enclosed room. the beam coping machine is profile coping the steel beams with plasma. To read more information about this beam coping machine visit our dedicated website for the MO ROBO 1200 . On this website you see machine specification, pictures and also an machine video how this machines works.

The MO ROBO 1200 is touch sensing the beam before the coping process starts. The touch sensing it done with the torch that is softly touching the beam on different positions and measures the dimensions and deviations in this way. Therefore, the robot can adapt based on what it encounters in this touch sensing phase by adjusting cutting parameters, if required.

The MO ROBO 1200 is touch sensing the beam before the coping process starts. The touch sensing it done with the torch that is softly touching the beam on different positions and measures the dimensions and deviations in this way. Therefore, the robot can adapt based on what it encounters in this touch sensing phase by adjusting cutting parameters, if required.

The robot cuts the steel with plasma cutting we have many different plasma cutting solutions to offer ranging from conventional up to high-definition plasma units for thin wall up to thick wall steel applications. We are offering both Hypertherm and Kjellberg plasma systems on our robotic systems. Obviously, we can advise you on the right suitable plasma type for your requirement.

If you have a request for such a robotic coping machine for 3D cutting your beams or other structural steel workpieces contact us for consultationconsul and quotations on mail@mueller-opladen.de

If you have one of our robotic coping machines installed in your factory, than you could send CAD files with profile cuts to the machine from your office and the coping robot will cut it accordingly.

Beam coping machines is widely used in the steel construction industry for example in the construction of bridges, building, train stations or stadiums. With the MO ROBO 1200 robot that Müller Opladen is offering for the steel construction industry you are able to raise the output of your coping activities for structural steel a lot.

Our robotic machine is not only a machine for coping but it is really a completely automated production line for processing 3D cutting of different kinds of structural steel workpieces such as H-Beams, T-Beams and I-beams. It is a robotic cell with a Kuka robot that 3D cuts with plasma the required shapes out of the steel workpieces and there is an infeed length measuring conveyor to this robotic cell and at the back there is an outfeed conveyor. We are even able to provide supply and dispatch buffers with this production line for coping steel workpieces.

Contact us on mail@mueller-opladen.de for your machine inquiries or request for quotations.

Müller Opladen is engineering and manufacturing 3D thermal cutting machines since the 1950s. Therefore, the company has a vast experience and knowhow on manufacturing and developing machines for the 3D coping and 3D cutting.

Visit our website for our beam coping robot for more information, machine specification, pictures and videos of the machine in operation. Based on your structural steel coping request we can provide a machine suitable for the job. We always work from a standard MO ROBO 1200 machine but based on the customers needs we can adapt.

On the different plasma options from Hypertherm or Kjellberg that we provide we can advise you to find the best application for your fabrication job. We are the machine manufacturer that will be your partner in provide a machine that really suits your needs.

Contact us for your coping machine inquiries on mail@mueller-opladen.de