MÜLLER OPLADEN technology is a key element at the competence center for rail vehicles

In Kragujevac, Serbia, something unique is being created. For this is where Siemens is building a hypermodern manufacturing center for rail vehicles in cooperation with the domestic MIND Group. In addition, suppliers from the industry will be located here to pool the process from the engineering stage through to the assembly of complete vehicles. For this project, MÜLLER OPLADEN has realized – most recently in 2019 – several customer-specific systems, which are used for efficiently welding the longitudinal seams on the roofs of Siemens passenger railcars.

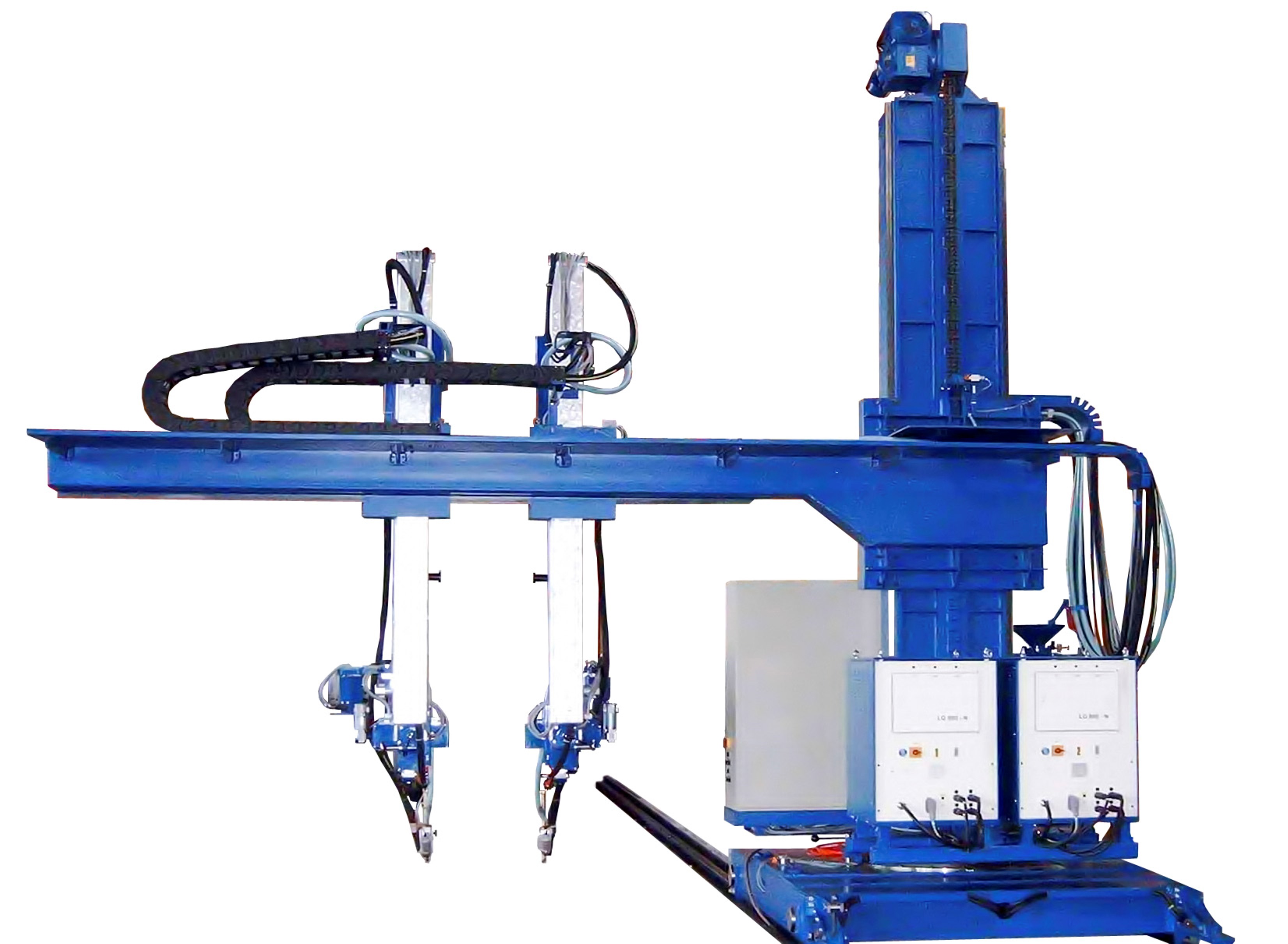

These MO longitudinal seam welding machines each have two welding heads for the magnetic pulse welding process, which are optimally positioned in relation to the weld seam on the large-surface components by means of heavy-duty longitudinal, transverse and vertical running gear. The undercarriage with its ball-bearing flange wheels is designed for the track gauge of 1,425 mm typical of railroads. AC servo drives ensure optimally controllable feed speeds of 2 to 200 cm/min for precise and speedy work processes. The two welding units are attached to the 5,000 mm long transverse boom – each with a wire feed case and torch. Each torch is precisely guided by two tactile scanning systems. The control unit is mounted on the undercarriage so it travels with the torch. The system is conveniently operated by remote control with a joystick.