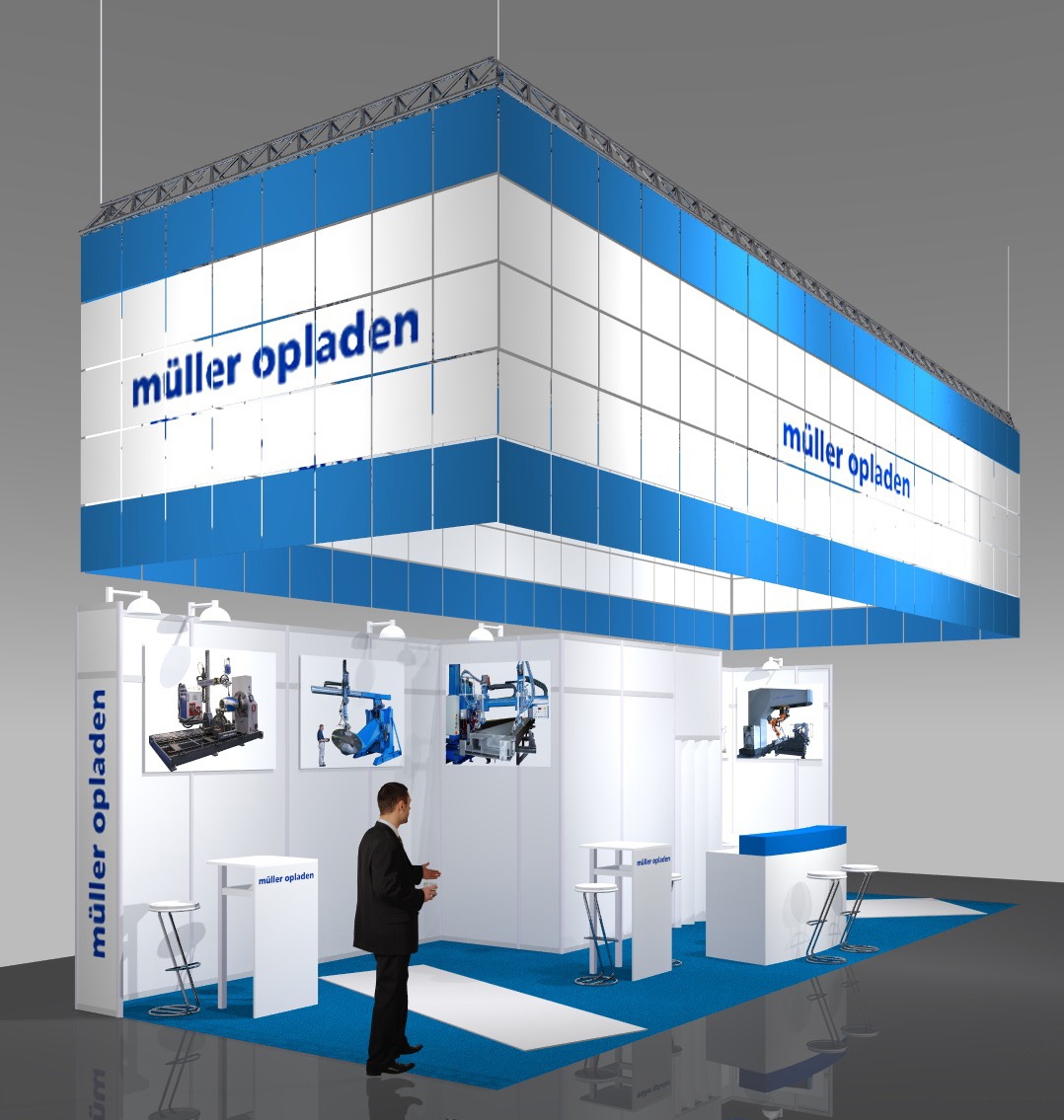

Modular system of high-grade standard components saves time and money

In Düsseldorf, MÜLLER OPLADEN is presenting a modular circumferential welding system, enabling customer welding requirements to be satisfied at short notice within 4-8 weeks and little expense. The circumferential welding system on show is designed specifically for Flexonorm compensators and is used for the TIG-welding of cylindrical components weighing up to 100 kg with diameters of 30 to 200 mm and lengths of up to 1,500 mm in an automated process.

More The use of standardized components, such as

– a drive station based on a MO-DT 100 HW125 welding turntable, and

– a torch feed system comprising a MO-BST 180/100 torch positioner with a pipe clamping system as well as pneumatic, motor-driven and manual supports from the MÜLLER OPLADEN module series, makes rapid realization possible.

In combination with selected standard components for manual or powered adjustment of the torch positioner or tailstock, the components described above form the basis for competitively priced solutions.

For TIG welding, we are employing a model from Fronius at the customer’s request. The components are circumferentially welded bluntly without seam preparation. The welding process is controlled by means of arc height regulation. As soon as the arc length changes, the control of the MÜLLER OPLADEN system receives a signal, causing the variation to be corrected by means of an electric height support. In the integration of current sources, MÜLLER OPLADEN is absolutely independent of make and can integrate any model desired by the customer into the system.