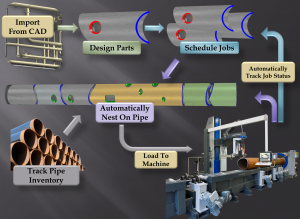

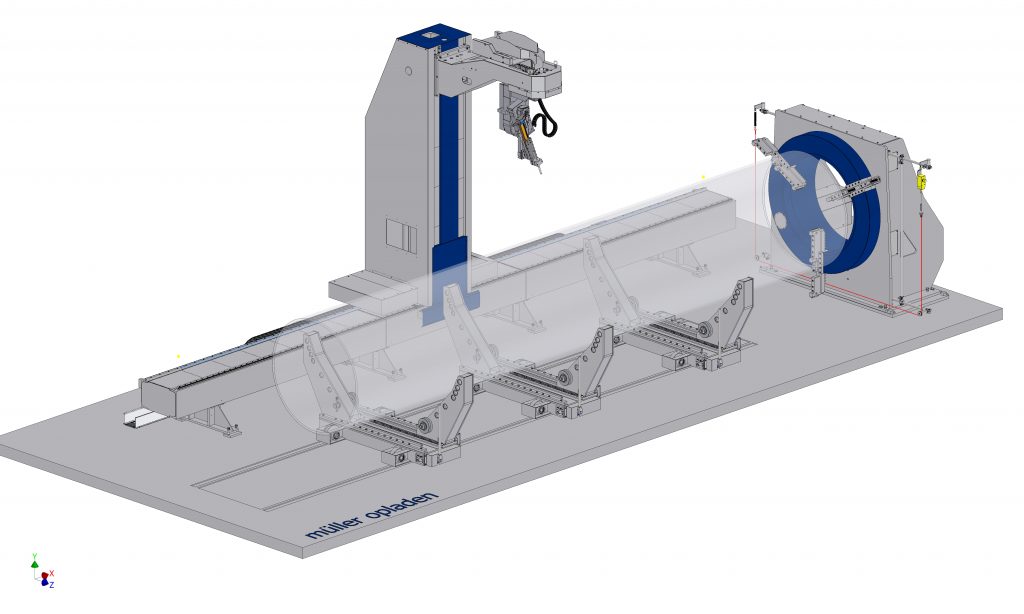

The pipe cutting and beveling machines that Mueller Opladen offers are stationary machines that do the cutting of the steel with thermal cutting processes such as oxy-fuel cutting and plasma cutting. With these cutting sources the machines could 3D profile cut the pipe and one of the operations it could also do is cutting and beveling of the pipe.

The machine has a vertical column with on a slide a cutting arm, this arm it could move in different angles to get the required cutting or beveling angle on the steel pipe or tube. Visit the website of Mueller Opladen to see the different pipe cutting and beveling machines we offer.

One of the machine series that covers the majority of the pipe diameters in the pipe fabrication market is the MO-Compact, we offer this machine in a 16”, 24”, 32” and 36” machine model they all start at a minimum diameter of 2”. This means that our MO-Compact 900 is a 2” to 36” stationary pipe profile cutting machine that can also do straight cutting and bevel angle cutting for welding preparations. Visit the website of the MO-Compact to read more technical information and to watch the video to see how this machine operates. If you are interested in this machine we can always provide a machine demonstration in our factory near Cologne in Germany.

Contact us for quotations or questions on mail@mueller-opladen.de

Other pipe cutting and beveling machines that Mueller Opladen offers are the MO-Classic and the  MO-Heavy-Duty. The MO-Classic is a machine with one CNC axis more than the MO-Compact which makes the machine able to cut besides round workpieces also square profiles if extra options are considered when investing in this machine. The MO-Classic machine series covers pipe diameter ranges from 2” to 80” with different machine models.

MO-Heavy-Duty. The MO-Classic is a machine with one CNC axis more than the MO-Compact which makes the machine able to cut besides round workpieces also square profiles if extra options are considered when investing in this machine. The MO-Classic machine series covers pipe diameter ranges from 2” to 80” with different machine models.

Visit this webpage for more information on the MO-Classic.

This MO-Classic machine also cuts and bevels with thermal cutting processes such as oxy-fuel cutting and plasma cutting. This means that a lot of heat is brought into the cutting process of cutting the pipe.

Contact us for quotations or questions on mail@mueller-opladen.de

The profile cutting machines that we manufacture all profile cut with cutting torches to create reliefs, shapes and holes in the pipe or tube. For pipe cutting and beveling we use a pipe bevel torch angle to do the cutting of the angle for beveling to do for example the V-bevel 30 degrees or a V-bevel 37.5 degrees as a good welding edge preparation for further welding.

The profile cutting machines that we manufacture all profile cut with cutting torches to create reliefs, shapes and holes in the pipe or tube. For pipe cutting and beveling we use a pipe bevel torch angle to do the cutting of the angle for beveling to do for example the V-bevel 30 degrees or a V-bevel 37.5 degrees as a good welding edge preparation for further welding.

Using a pipe bevel torch angle is also possible when we are cutting a hole out of the main pipe and if the edge of this hole cutting needs to be chamfered or bevelled. The torch of the profile cutting machine will go to a 37.5 degrees angle to bevel the steel into this position. With our thermal cutting machines we can only do one angle cutting during the beveling of steel.

Visit the MO-Compact website for machines that could be used for pipe cutting and beveling.

Our profile cutting machines like the MO-Compact and the MO-Classic you could consider as well as automatic pipe beveling machines, but most end customers buy our equipment not only for pipe beveling because the machines are capable of doing much more that only creating V-bevel angles and straight cutting of pipes and tubes.

Watch the MO-Compact video on this webpage to see what kind of profile cutting, beveling and straight cutting the machine can do on pipes.

The profiling machines for pipes that we manufacture are able to do saddle cutting, miter cuts, slot cutting, hole cutting, branch pipe connections and more.

Go to this link to see all different pipe profiling machines that can be used as automatic pipe beveling machines as well.