Our machines are using a pipe flame cutting process to profile cut steel on round or square workpieces. Mueller Opladen has experience in pipe flame cutting process such as oxy-fuel cutting and plasma cutting for many years. More important is that the machines are mechanically and electrically equipped in such a way that with the accurate cutting process the pipe profile cutting process with oxy-fuel or plasma is still very accurate and according to the CAD files that are designed with all profile cutting shapes , reliefs and holes.

Visit our company website www.mueller-opladen.de to get an understanding on what kind of pipe flame cutting machines we can offer you for your profile cutting requirement.

In general we can offer you the following machine series:

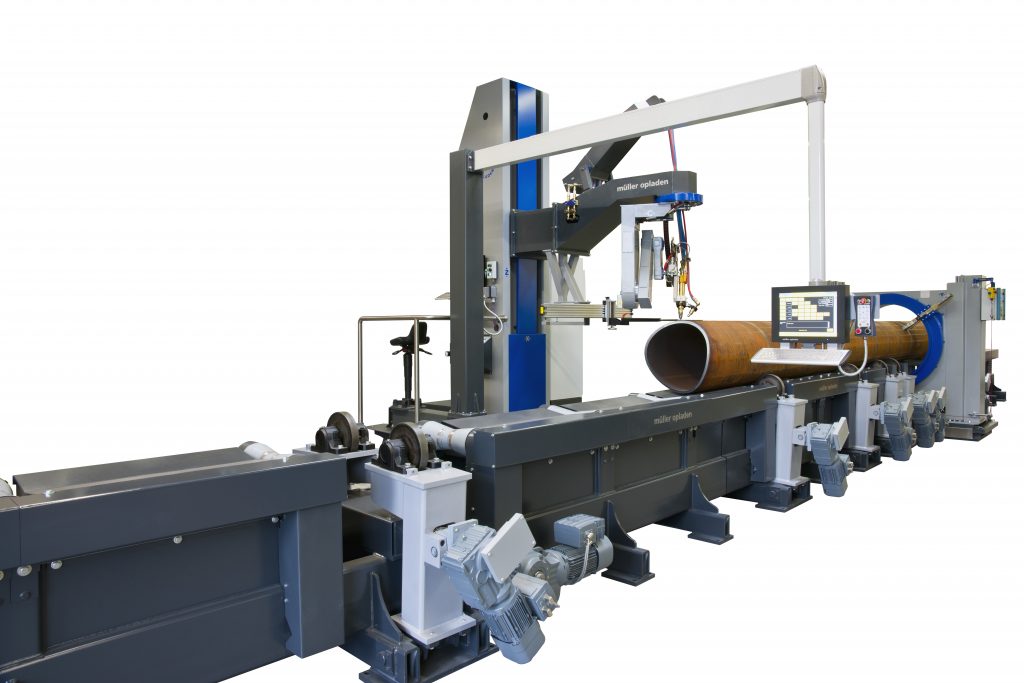

MO-Compact machines : profile cutting machines for round workpieces such as round pipe, tube and pressure vessels up between 2 “and 36”

MO-Classic machines: profile cutting machines standard for round workpieces such as pipe, tube and pressure vessels, but they optionally could be made suitable for square profiles such as box sections, square pipe and rectangular pipe. The pipe diameter it covers with all machine models is from 2 “to 80”.

MO-Heavy-Duty machines: profile cutting machines for only round workpieces such as pipe, tube and pressure vessels in the diameter range 80 “up to 160”.

Contact us on mail@mueller-opladen.de for more information and quotations on pipe flame cutting machines

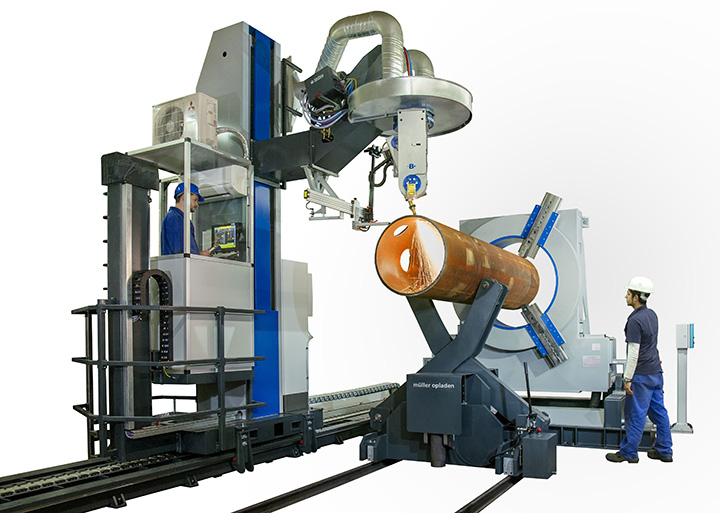

Mueller Opladen is manufacturing and selling world-wide stationary CNC controlled pipe flame cutting machines for 3D pipe and tube profile cutting. The machine with a robotic arm could do all cutting shapes as you desire in 3D.

To get a good impression about the cutting process of our pipe flame cutting machines it is best to visit the website of the MO-Compact and study the different machines within this machine series.

Most important watch the video of the MO-Compact to see how this pipe flame cutting process works on our pipe profilers.

We offer the MO-Compact machines in different machine models all covering different pipe diameter ranges for pipe flame cutting, below we provide you an overview of the different machine models and the pipe diameter range:

MO-Compact 400 , covering pipe diameters 2 ”to 16”

MO-Compact 600 , covering pipe diameters 2 ”to 24”

MO-Compact 800 , covering pipe diameters 2 ”to 32”

MO-Compact 900 , covering pipe diameters 2 ”to 36”

The MO-Compact series are designed for CNC profile cutting tubes, pipes and pressure vessels only. This means the machine is only capable of doing round steel objects. We have other machine series that are able to cut profile also square profiles this is our MO-Classic series.

Our MO-Classic machine series is the most versatile we have, with the 7 CNC axis the machine standard is designed for flame cutting and profile cutting round workpieces such as tubes, pipes and pressure vessels. But, to your MO-Classic machine you could add different rotating clamping mechanisms to do for example also box sections, square pipes and rectangular pipes.

Visit the webpage of the MO-Classic to see the video and read more about the different options we can offer you for flame cutting also square profiles on this machine.

Contact us on mail@mueller-opladen.de for questions or quotations on the machines.

Another option is to manufacture the MO-Classic with a tilt able chuck and if this chuck is put in a horizontal position it could be used as a fixation table for the flame cutting process of pressure vessel heads or so-called domes or dished ends. See the picture below.

Interested in one of the options we explained about? contact us on mail@mueller-opladen.de for questions or quotations on our machine solutions .

When we talk about flame cutting, it is mostly referred to as oxy fuel cutting like cutting with gasses such as propane or acetylene. Since the 1950s Mueller Opladen is manufacturing stationary machines for flame cutting pipes with oxy-fuel like propane or acetylene, with a CNC controlled and robotic arm the machine can perform all 3D profile cutting shapes as in your CAD technical drawing that you uploaded in the machine .

Go to the website of Mueller Opladen to get familiar with the oxy-fuel and plasma cutting machines for cnc pipe and tube profiling.

With flame cutting Mueller opladen is profile cutting tubes, pipes, and pressure vessels on their MO-Compact, MO-Classic and MO-Heavy-duty machines. Besides flame cutting machines for these round workpieces, that are mostly designed to profile cut metal pipes, Mueller is also offering flame cutting machines that are only manufactured and engineered for profile cutting square workpieces this is the MO-Robo.

The MO-Robo is engineered to profile cut with oxy-fuel and plasma girders, u-channels, H-Beams, T-beams, HEB-Beams, L-channels and box sections. Visit the website of the MO-Robo to see the two different machine models we offer.

The MO-Robo is a Kuka robot that is standing next to an infeed and outfeedconveyor in a closed cabinet.