MÜLLER OPLADEN’s 3D profiling machines use both plasma and oxy-fuel processes. What are the respective advantages?

Managing Director Ralf Hamacher: “Easy to use and cost-effective, the oxy-fuel process is ideally suited to cutting thick-walled pipes of up to 150 mm in steel construction – for example, in the offshore sector for oil and gas platform construction, wind turbines and steel construction. In addition, if I need a torch angle of well below 45 degrees and a tilt angle of 70 degrees, that’s out of the question with the plasma process for purely physical reasons.

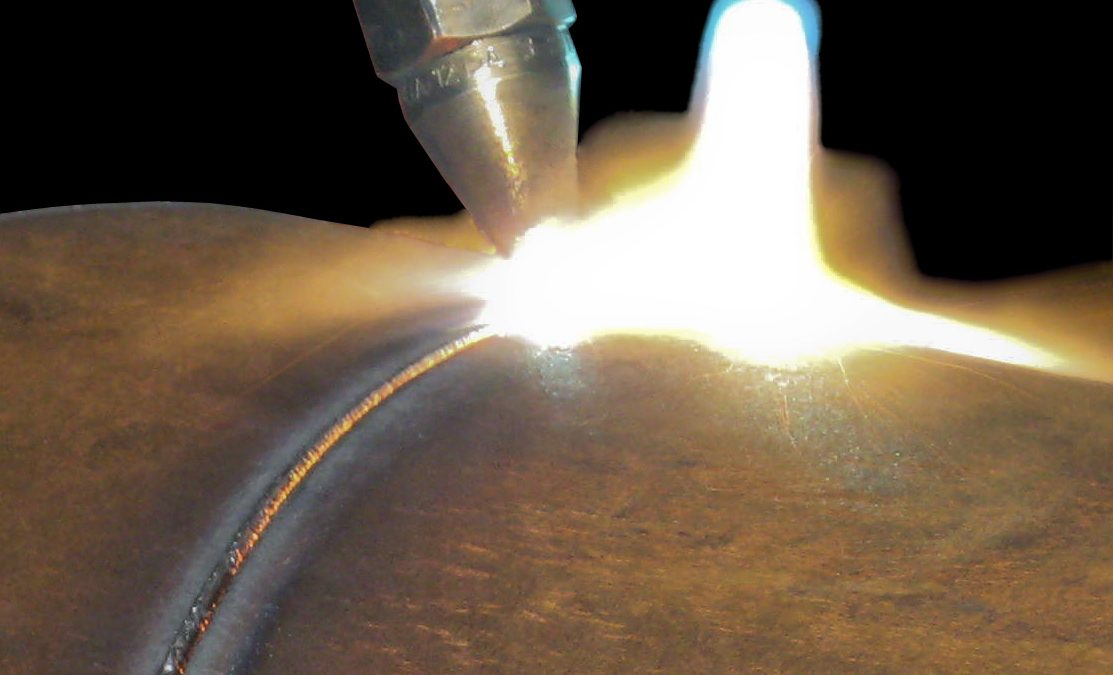

“For pipes with slightly thinner walls up to 60 mm, we use the plasma process. The cutting speeds are higher, the quality of cut is better and the welds are neater. For materials such as stainless steel, e.g. for food production plants, plasma is the only option. The consumption costs for the plasma process are significantly higher because the cathodes, nozzles, etc., have a significantly higher rate of wear. Furthermore, plasma sometimes calls for more expensive gases and extraction devices with filters.”

Talk to MÜLLER OPLADEN about the best process for your application.