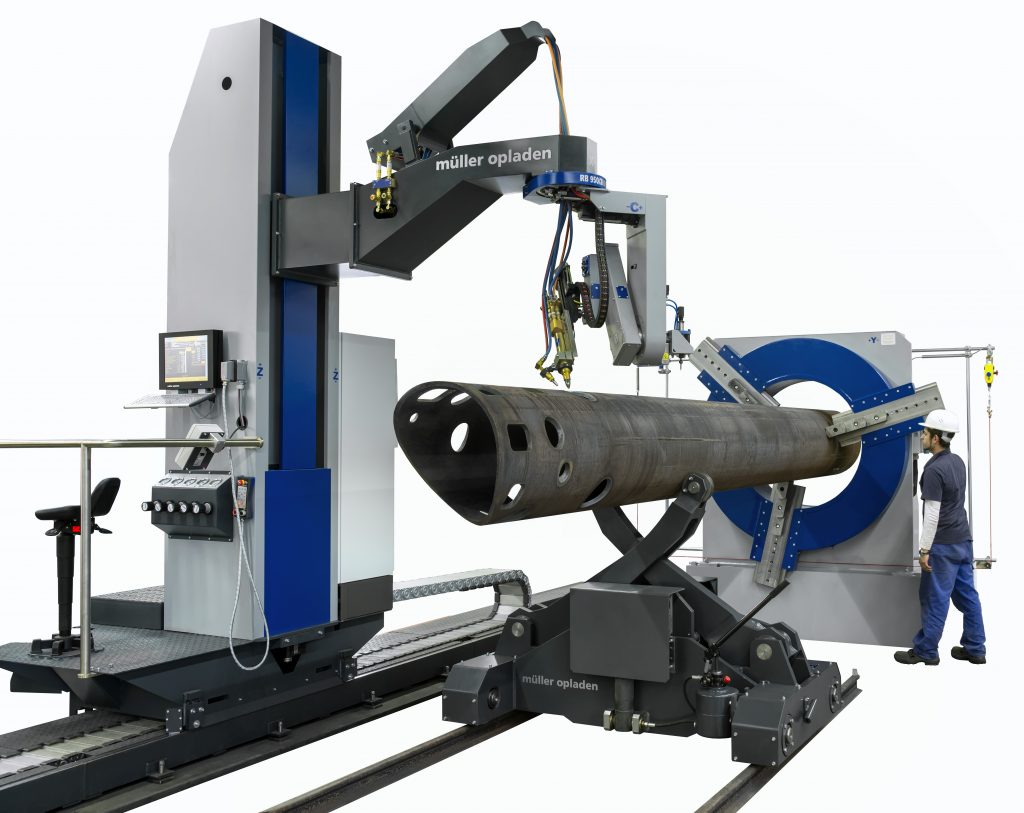

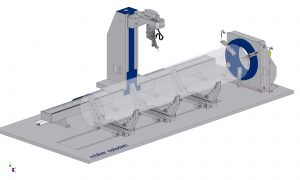

Mueller Opladen is the expert in manufacturing pipe profiling machines to cut and profile pipes with autogenous or plasma. The stationary pipe profiling machines from Mueller Opladen with different machine models cover the pipe diameter range of 50 to 4000 mm (2 ”to 160”) go to the company’s website to learn more about the different CNC controlled state-of-the-art pipe profiling machines .

The pipe profiling machines that Mueller Opladen offers are reliable machines, that are have the latest technology and we only high-quality machine parts. As a German machine manufacturer that operates in the pipe profiling market since the 1950s we always focus on providing the end customer in profiling the highest quality machines that are built for heavy duty industrial use.

Our MO-Classic series for pipe profiling is our most sold machine range, because it is having additional features compared to our more basic machine the Compact serie that sometimes is required for more complex 3D pipe cutting profiles that are required by the end customers.

You could also send us your pipe profiling request for quotation by email on mail@mueller-opladen.de

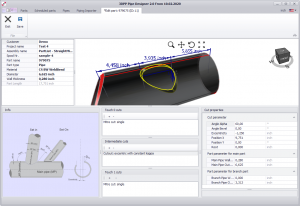

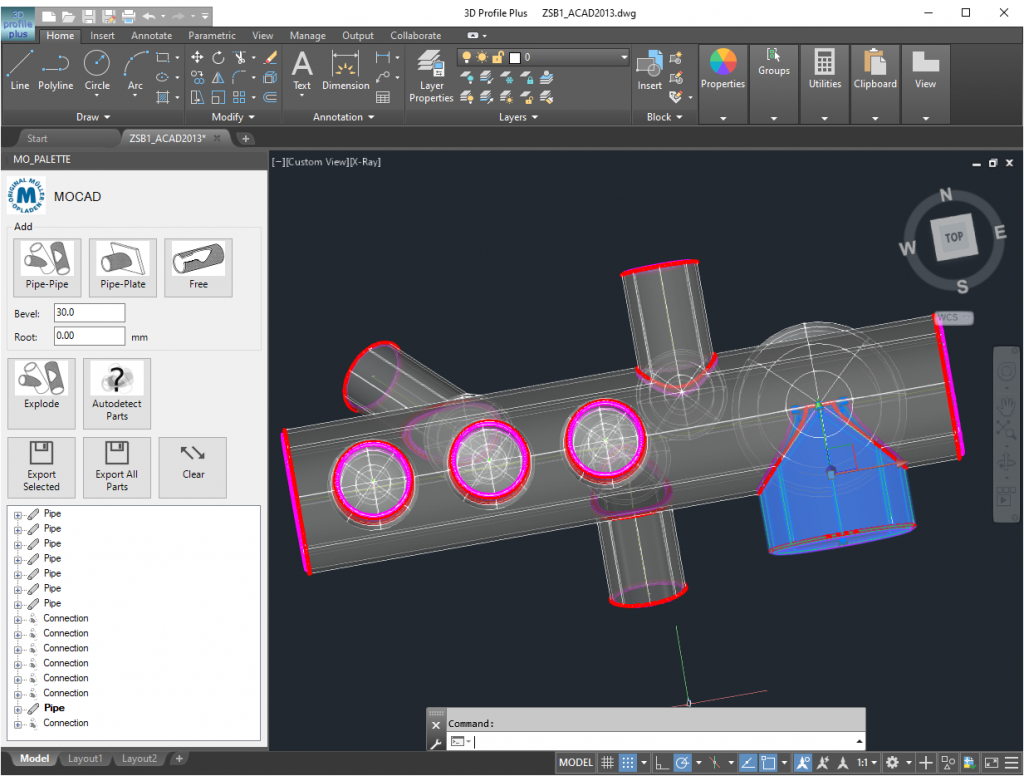

MO-Classic, CNC pipe profiling cutting machine with motorized ball gutter.The MO-Classic machines can be equipped with MOCAM software in order to upload your CAD files (from the actual profile cut on the pipe) and upload them in the machine software, after that these profile cuts could still be edited in the MOCAM software that we created.

This means you could add or change profile cuts on the CAD files that you upload in the MOCAM software. Furthermore, this software for pipe profiling and tube profiling allows you to rotate the pipe in a 3D view and see different angles of it. With this software you could send drawings from the office to the pipe profiling machine, the operator at the profiling machine can than still work and edit these CAD files in the MOCAM software.

Besides that, there is a modeling and nesting function to see if the branch pipe you are about to profile cut fits on the hole that you cutted before on the mother pipe. go to the MOCAM software webpage on the Mueller Opladen website for more information

We can provide you a presentation of the MOCAM software

contact us by email mail@mueller-opladen.de

Mueller Opladen is selling and installing world-wide stationary equipment for pipe profiling and tube profiling. In many cases the solution sold is a custom-made, based on the customers requirement for pipe profiling .

If the standard machines from the website are not the 100% solution that you require for pipe profiling than contact us for your special request on mail@mueller-opladen.de

Besides pipe profiling machines we also offer multiple axis CNC machines to profile square pipe, rectangular pipe, vessel heads, dished ends, and different kinds of steel beams such as H-beams, U-Channels, I-beams and so on. To find out more about different profiling machines go to the website of Mueller Opladen .

Ever since the first mechanical oxy-fuel machine for pipe profiling was introduced by Mueller Opladen in the early 1950s, it has since that first machine undergone consistent further development. The development in pipe profiling came mostly because Mueller got more experience in the production process and engineering but also because of the feedback they got from customers and the experience that was created by doing many profile cuts when testing the equipment.

Visit the website www.mueller-opladen.de

The machines of the current generation are equipped with plasma profiling and oxy fuel profiling options. Nowadays the CNC pipe profiling machines from Mueller Opladen are equipped with up to 9 CNC axis that are all controlled over CNC software where the operator could upload and edit CAD / CAM files. Click here to go to the product page for CNC pipe profiling machines.

Or send us directly and inquiry by email for the profiling machine you are looking for on mail@mueller-opladen.de

If you have specific question ask them and our responsible sales representative will contact your shortly.

The expertise with CNC profiling at Mueller Opladen is at a very high level because of the decades of experience in building the pipe profiling machines and engineering of those stationary machines. All machines that Mueller Opladen sells worldwide for pipe profiling are related to thermal cutting and shaping of metal pipes . The pipe fabrication industry, vessel manufacturing industry and other industries such as the offshore construction and ship construction industry are using ways to cut and shape pipes by thermal cutting that are all related to the long existing Autogen or so-called flame cutting.

The most CNC pipe profiling machines that are sold by Müller are having autogenous and plasma cutting as thermal cutting sources to choose from for profile cutting.

Go to our webpage for the MO-Classic series to get an understanding about the 7 axis CNC machine for CNC pipe profiling, this machine series offers different types for different diameter ranges. This machine series goes up to 2000 mm diameter in different models.

Contact us for more information at mail@mueller-opladen.de

Müller created its own software level for the controls in the machine for editing, nesting and importing CAD files from different sources such as Solid works, Tekla, Inventor, AutoCAD and Solid Edge.

The software that Muller created on Corobs is easy to work with and simple it really enables the user quickly to check the workpiece in a 3D setting and add if necessary, cuts to an existing drawing when uploaded.

Contact us for more information at mail@mueller-opladen.de