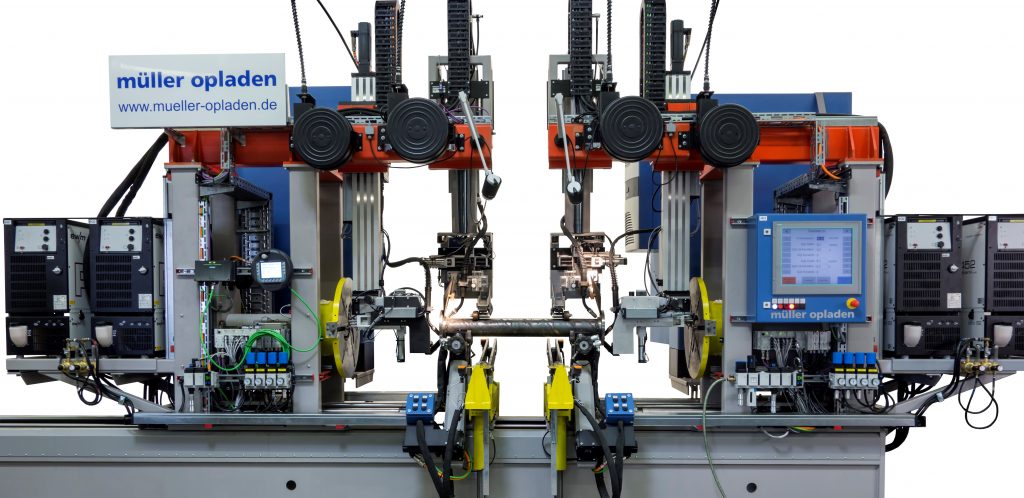

This pipe to flange welding machine is simultaneously welding the inner and outer welds on both ends (means 4 torches simultaneously welding) of the pipe, to create the connection between the pipe and the flange.

These pipe to flange welding machines are often used in shipbuilding and petrochemical industries where certain quantities of 6 meter long pipe spools are required every month. When there is enough volume per month of these spools with flanges than investing in such an automated welding machine is worthwhile looking at. This pipe to flange welding machine is another of our pipe spool welding machines that we offer. Our market approach is to provide the most high-quality machines in the industry for that particular purpose, next to that are we manufacturing robust and sturdy machines that are reliable and state of the art.

The welding process that we offer on this machine is standard GMAW welding and the connection between pipe and the slip-on flange is a socket weld. Alternatively, we could equip this pipe to flange welding machine with a butt-welding process to be able to weld also neck flanges to pipes.

The pipe to flange welding machine we have in one model that is covering outside pipe diameters from 1” to 18”, watch the videoclip of this special pipe spool welding machine on this webpage.

Contact us for your enquiry on an automated machine for pipe to flange welding on mail@mueller-opladen.de

years ago, Mueller Opladen engineered an automated pipe to flange welding machine for a large shipyard with a repetitive demand for up to 6 meter long spools with on both ends a one slip on flanges after that this pipe to flange welding machine became a standard machine with automated welding solutions.

Our stationary pipe to flange welding machine is an automatic welding machine for welding straight pipe to flanges. The machine could weld one up to 6-meter-long pipe to two slip on flanges (one on each side) with a fillet weld process internally and externally. The machine is having Siemens PLC software to control the many different machine axis, on top of the Siemens software we have integrated our operator level.

This automated welding machine is in fact welding pipe spools existing of only one pipe with on both end a flange. The machine could be equipped with automatic loading and unloading of pipes, the flanges have to be put by hand or overhead crane on to the two chucks and clamped.

When all parts from the pipe spool are loaded in the pipe to flange welding machine, first the machine is scanning the socket weld connections between pipe and flange. If this step is done the information of the scanning process is being transferred to the software. With this data the machine able to use adaptive control in the welding process to be able to do a high-quality girth weld that is not having any lack of fusion or welding defects on x-rays. This is one of the key aspects of this machine that makes this automatic welding machine a trustable machine that is providing your pipe spool activities a continues high quality welding result.

This pipe to flange welding machine is suitable for for high volume pipe spool industries that ask for a repetitive work and quality level.

When you are welding a flange to pipe connections it could be interesting automating this welding process with our stationary pipe to flange welding machine that welds automatically a 6 meter pipe to two slip on flanges on both ends of this pipe. This machine is suitable for repetitive and high-volume fabrication of this pipe spools. We see that especially in shipbuilding industries and in shipyards these machines are being sold world-wide. But also, petrochemical pipe spool fabrication factories might be suitable for using such a machine in production.

Another example of a pipe spool welding machine that we offer for welding pipe to flanges is our circumferential welding machine, this single sided machine where one pipe to one fitting is aligned and clamped in the rotating chuck. Therefore, is this circumferential welding machine also suitable for lower volumes than the pipe to flange welding machine.

You could also contact us on mail@mueller-opladen.de for advice and quotations on of these welding machines.

The circumferential welding machine, the column and boom and the pipe to flange welding machine are all three pipe spool welding machines. Each of them is only used for different purposes.

For each of this welding machine the welding process can be choosen by the end customer in the offering stage. You could choose from MIG, MAG, GMAW, GTAW, SAW or Plasma welding.

The circumferential welding machine is a machine where you could weld a straight pipe spool with that has a butt-welding connection, this means that a pipe to fitting connection can be easily welded. Standard this pipe spool welding machine is designed for outer pipe diameters up to 508 mm diameter ( O.D 20 inch) But, based on a customer requirement we could offer custom made based machine designs that are based on the principal idea of our circumferential welding machine.

Contact us on mail@mueller-opladen.de for your automated pipe spool welding machine request.

As explained another pipe spool welding application we can offer with our column and boom welding machine when it is a sub-assembly to a pipe spool. When it is a straight spool it is better to weld it with the circumferential welding machine, when the it is an add on and a more complex angle for the welding torch to weld on an existing spool we can offer solutions with our column and boom welding equipment