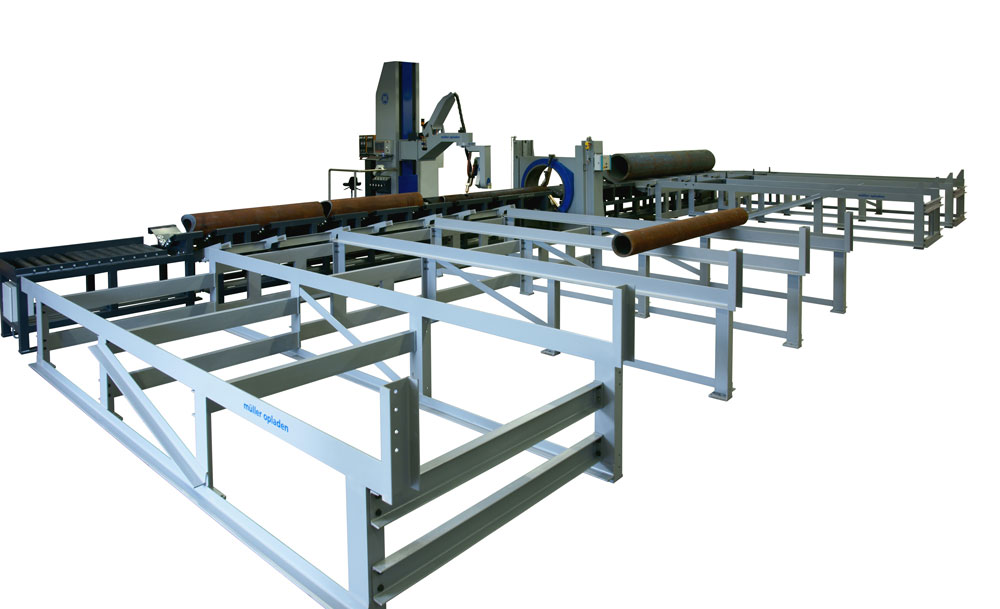

Pipe profiling machine with logistics

There are diverging trends between North America and the rest of the world in the loading of pipe profiling machines. In the USA, about 80% of these machines are sold with automatic logistics, while in the rest of the world only about 20% of the machines are ordered with logistics.

What are the reasons or advantages that make so many customers in North America invest more in pipe logistics?

- At least 30% higher productivity

- ONE machine operator for materials handling and cutting tasks

- Pipe infeed from outside means less space required in the hall

- Much reduced accident risk at the machine due the elimination of loading by crane

- Much reduced accident risk for the operator due to the elimination of the handling of the pipe carriage and cut items

- Cut items and waste cannot fall, so less potential damage to materials and less noise

Procedures without logistics

On a single pipe profiling machine, the pipes are placed, e.g. by an overhead crane, on the pipe carriages, which are moved in turn on rails. Beforehand, the operator has to prepare the pipe carriages to receive the pipe by mechanically or hydraulically adjusting the roller positions to the respective pipe diameter.

Once the pipe is on the pipe carriage, the operator pushes the loaded unit into the machine's chuck and clamps it there before pipe cutting can begin.

During the cutting process as well, the operator also has to move the pipe carriages under the pipe sections being cut so that the cut parts do not fall. To do this, the operator very often needs the help of the overhead crane to clear away cut parts on the pipe carriages and make space for the next part to be cut.

The productivity of the pipe cutting machine therefore depends heavily on the constant availability of an indoor crane. If the machine operator cannot operate the crane himself, an extra crane operator is needed.

The advantages of logistics

The pipe profiling machine with pipe logistics, on the other hand, enables highly efficient pipe cutting with just a single machine operator who does not have to wait for a crane to load or offload the pipes.

In many cases, the pipe storage table and infeed conveyor are positioned outside the production hall proper. The pipes stored outside can then be loaded onto the pipe storage table by forklift truck or outdoor crane fully independently of the machine and its operator.

The machine operator inside can load a pipe onto the infeed conveyor at the push of a button and then feed the pipe through an opening with a roller shutter onto the machine's cutting conveyor. This process is many times faster than crane loading at a normal machine.

The cutting process on the pipe profiling machine is then fully automatic, as the operator does not have to halt the process between individual cuts, e.g. to reposition the pipe carriage or clear away cut parts. This speeds up the cutting process considerably.

After the complete pipe has been cut, the operator offloads it from the machine at the push of a button. The pipe is offloaded either laterally by ejector arms onto a pipe table alongside the machine's cutting conveyor or lengthwise onto an outfeed conveyor as an extension of the cutting conveyor. This process is also many times faster than the usual offloading by crane.

Even if a single pipe profiling machine is optimally assisted by an overhead crane, the productivity of a machine with pipe logistics is still some 30% higher.