MO Robo schneidet verschiedenste Träger, Rundrohre und Vierkantrohre

Verarbeitet Träger bis 1.200 mm und 12 Tonnen

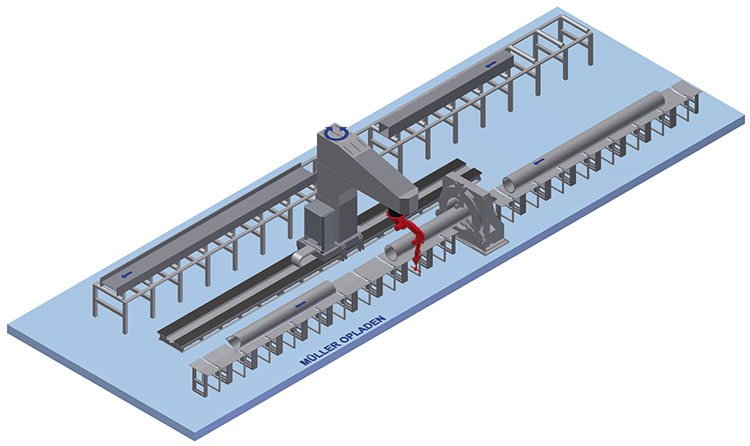

Bei der MO Robo-Serie handelt es sich um Roboter-Maschinen, die primär für das umfassende Schneiden von Trägern (H-Träger, U-Träger, L-Träger und I-Träger) vorgesehen sind – darüber hinaus aber auch Rundrohre und Vierkantrohre schneiden können. Träger können bis zu einer Länge von 1.200 mm und bis zu einem Gewicht von 12 Tonnen bearbeitet werden. Sofern die verschiedenen Werkstücke vom Träger über das Vierkantrohr bis zum Rundrohr zu profilieren sind, werden die Maschinen mit 9 CNC-gesteuerten Achsen ausgestattet. Die Werkstücke werden auf die jeweiligen Trägerschneidbetten per Kran eingelegt. Alternativ bieten wir die Maschine auch ausschließlich für Träger mit Schneidzelle sowie automatisierter Zu- und Abführung an.

Die maximalen Dimensionen für Rundrohre und Vierkantrohre sind der Tabelle mit den technischen Details zu entnehmen. Detaillierte Informationen werden auf Anfrage zugestellt.

MO 200/600/800/9 Robo

mit 9 CNC-Achsen für Träger mit einer maximalen Breite von 600 mm, für Vierkantrohre mit maximal 420 mm x 420 mm sowie für Rundrohre mit einem maximalen Durchmesser von 1.000 mm inklusive Autogenschneidsystem, höhenverstellbarem Spannfutter, motorisierten Zuführrollgängen, automatisiertem Schneidrollgang bzw. Schneidtisch und motorisierten Abführrollgängen

| Technische Informationen / Maschinenserie: | MO 200 Robo | MO 600 Robo | MO 800 Robo | MO 1200 Robo |

|---|---|---|---|---|

| Gewicht Standardmaschine in kg: | 7.000 | 12.000 | 13.000 | 16.000 |

| Anzahl der CNC Achsen: | 7-9 | 7-9 | 7-9 | 7-9 |

| Max. Gewicht Werkstück in kg: | 4.000 | 8.000 | 12.000 | 12.000 |

| Min. - max. spannbarer Rohrdurchmesser in mm: | 50 - 406 | 50 - 610 | 50 - 812 | 50 - 1.220 |

| Max. Spannfutterdurchgang in mm: | 400 | 400 | 400 | 650 |

| Min. - max. spannbares Maß für Vierkantrohre in mm: | 100 x 100 / 240 x 240 | 100 x 100 / 240 x 240 | 100 x 100 / 240 x 240 | 100 x 100 / 420 x 420 |

| Min. - max. spannbare Breite für Stahlträger in mm: | 50 - 200 | 50 - 600 | 50 - 800 | 100 - 1200 |

| Min. - max. spannbarer Durchmesser für Klöpperböden in mm: | - | - | - | - |

| Min. - max. schneidbare Werkstücklänge in mm:* | 300 - 12.000 | 300 - 12.000 | 300 - 12.000 | 300 - 12.000 |

| Min. - max. Wandstärkezum Schneiden mit Autogen / Plasma in mm:* | 5-120 / 1-80 | 5-120 / 1-80 | 5-120 / 1-80 | 5-120 / 1-80 |

| Max. Brennerneigungswinkel Autogen / Plasma in °:*** | +/- 70 / 45 | +/- 70 / 45 | +/- 70 / 45 | +/- 70 / 45 |

* bei vertikaler Brennerstellung