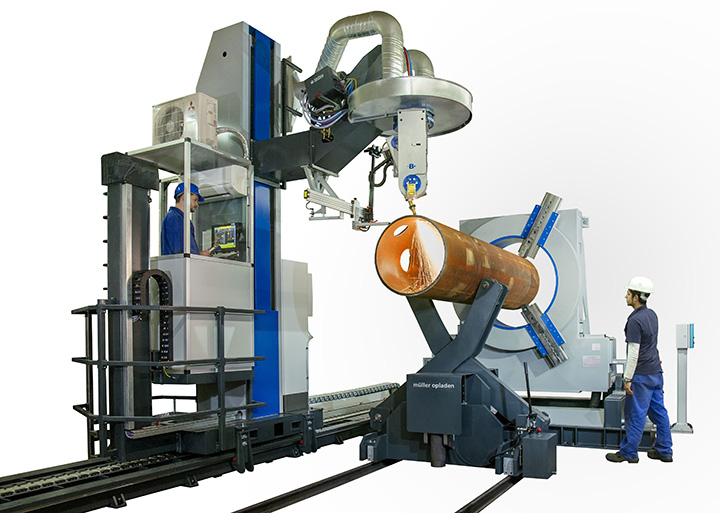

3D thermal cutting machines for round pipe and vessels

MÜLLER OPLADEN machines for round workpieces are available in different machine series and models altogether we cover 2" to 160" diameter (50 to 4064 mm).

Our 6 CNC axis system enables you to adapt on deviations in the outer diameter and still perform an accurate 3D cut with plasma or oxy fuel.

Our machines are reliable, state of the art and have the latest software technology for 3D profile cutting of round workpieces. The machines can be quickly programmed online, offline or via CAD/CAM modules for the profiles to be cut with the aid of already available cutting macros.

For the plasma cutting we work with both Hypertherm and Kjellberg and we can offer you the conventional and high-definition plasma sources. On oxy fuel cutting we can offer propane and acetylene cutting.

See the below overview with different machine models for round pipe and vessel profile cutting.

Please contact us for enquiries and advice

contact us for enquiries:

|

Pipe and Vessel 3D profiling |

|

|

|

Machine series |

Pipe diameter range in mm |

Pipe diameter range in inches |

|

From 50 to 914 mm |

From 2" to 36" |

|

|

From 80 to 2032 mm |

From 3" to 80" |

|

|

From 200 to 4064 mm |

From 8" to 160" |

Machines series 3D pipe profiling

Plasma and oxy-fuel are available as cutting processes. The main differences between the various series can be seen from the table on the opposite page.

The CNC axes are as follows:

- Rotation of the workpiece inside the chuck system (Y-axis)

- Longitudinal movement of the cutting head along the workpiece axis (X-axis)

- Oscillatory movement of the cutting head (B-axis)

- Rotation of the cutting head (C-axis)

- Height adjustment of the cutting head by a measuring system in the event of surface deviations of the workpiece (Z-axis)

- Torch distance correction in relation to the cutting angle during the cutting process (W-axis)

- Transverse movement of the cutting head at 90° to the workpiece axis (V-axis)