Müller Opladen becomes part of Voortman Group

As of January 1, 2023, Müller Opladen GmbH has become a part of Voortman Steel Machinery, a internationally renowned manufacturer of CNC steel processing machines and

Müller Opladen becomes part of Voortman Group

As of January 1, 2023, Müller Opladen GmbH has become a part of Voortman Steel Machinery, a internationally renowned manufacturer of CNC steel processing machines and

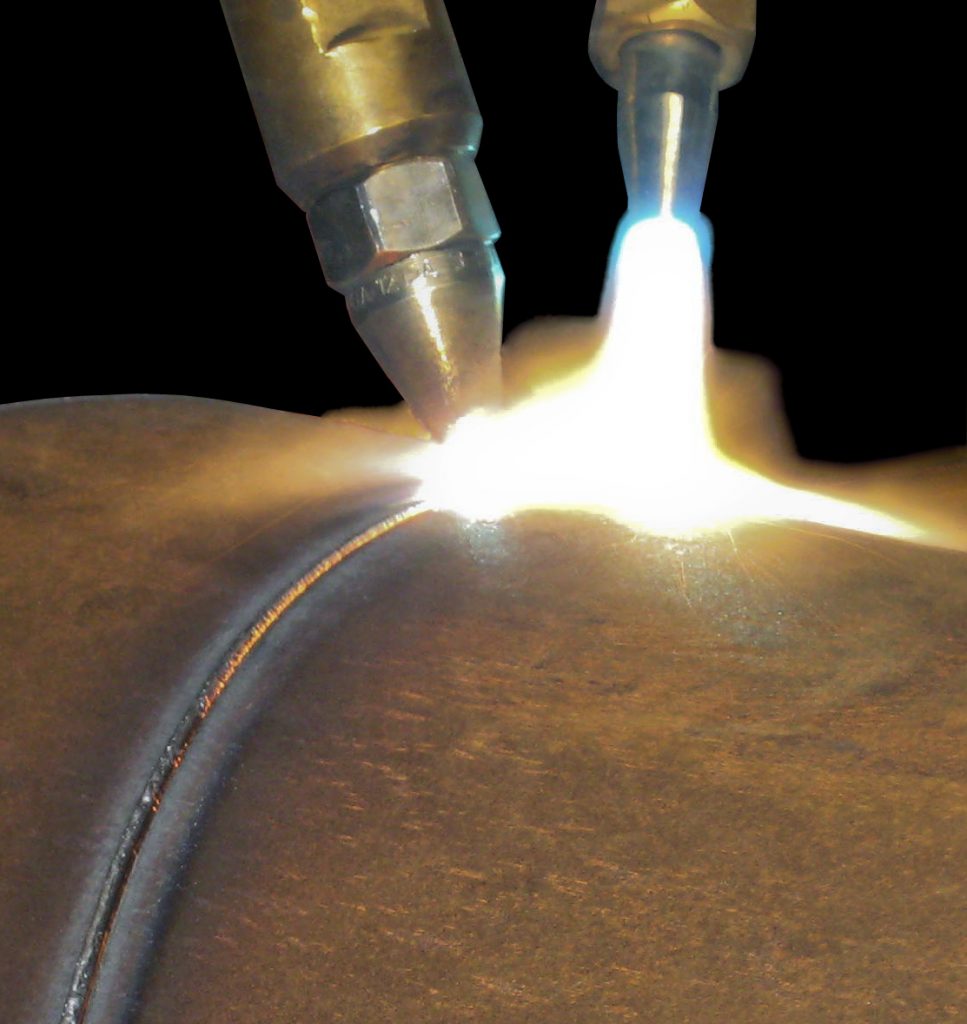

Precision cutting replaces time-consuming sawing

Efficient production of high-quality district heating pipes at Isoplus – Instead of sawing pipes to length and beveling the pipe ends in a further work step, Isoplus

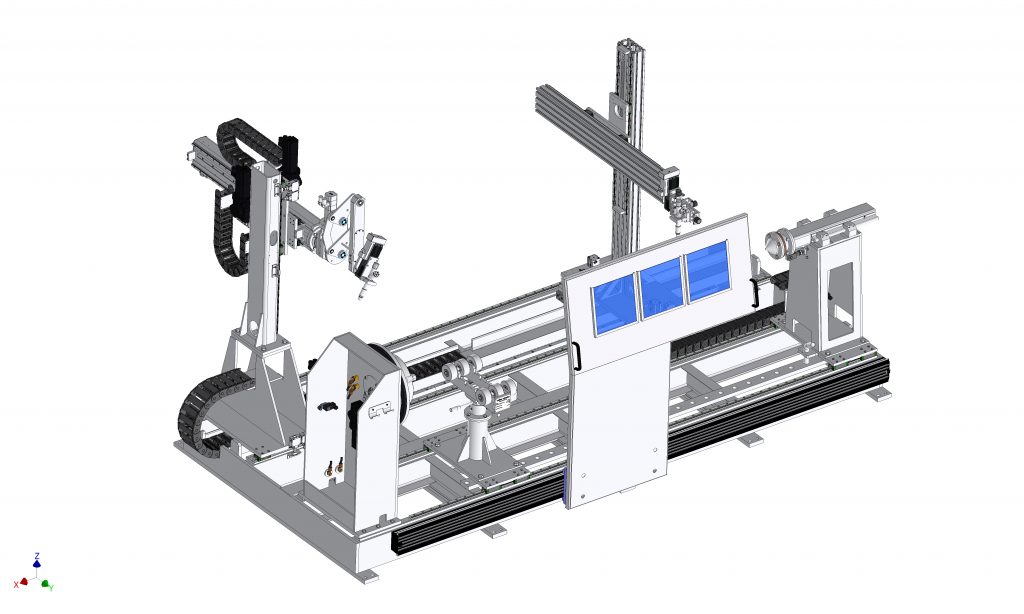

Serbia: 6-axis system for top quality and precision

Steeltec is one of Serbia’s leading industrial companies and has become successful with the production of cold-formed profiles made of galvanized steel sheet and plate. With

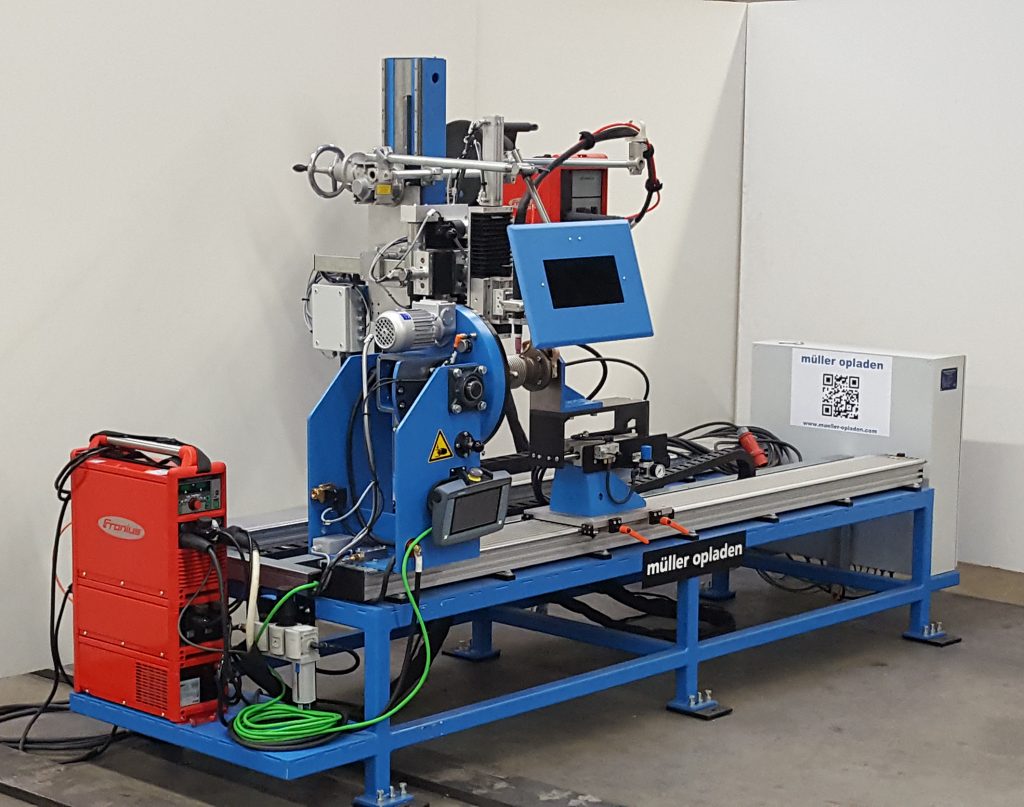

USA: From old to new – exemplary retrofit

Is your machine getting on in years? No problem for MÜLLER OPLADEN. We update it. We retrofitted an old 5-axis pipe profiling machine from Vernon Tool

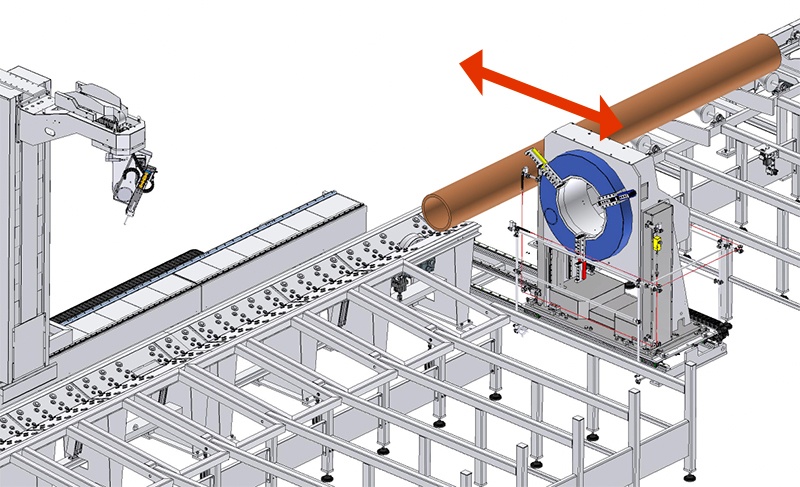

Mexico: Cutting system plus logistics quickly up and running

MÜLLER OPLADEN has now commissioned a complete production line consisting of a profiling system and logistics as a “blended machine” at its customer ICA (part of

For Years the Standard for Top-Quality Cutting – Stahlrohr GmbH trusts in MÜLLER OPLADEN technology

At Stahlrohr GmbH, a 3D pipe profiling machine from MÜLLER OPLADEN has been in reliable operation for more than 10 years – at times in 2-shift

David Harris – Welcome to the MO-Team!

David Harris (42) strengthens the sales team of WATTS MUELLER in North America. He brings a wide range of experience to optimally support our customers. He has

Million-dollar order for shipyard in Russia

A huge new shipyard has been built near the Russian port of Murmansk. Here the process equipment for a second LNG plant is to be built

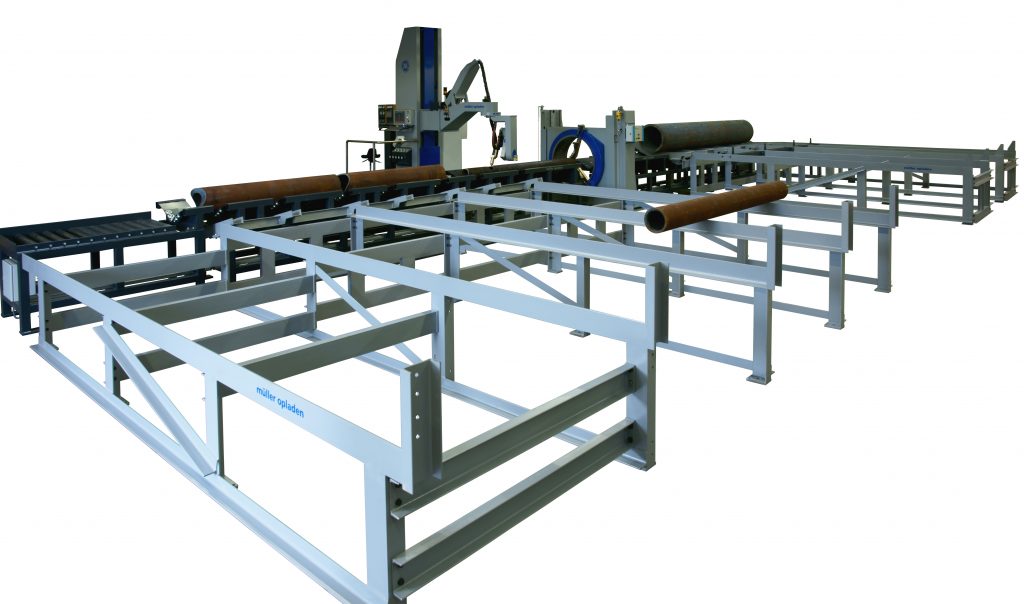

30% higher productivity with intelligent pipe logistics

In North America, MÜLLER OPLADEN already supplies approx. 80% of its pipe profiling systems with automatic logistics, the figure being much lower for the rest of

GEMA Apparatenbouw’s own 3D cutting machine opens up new opportunities

Speeding up production, having more control, cutting costs and generating work in its own production department – these were the main reasons for GEMA Apparatenbouw in