In North America, MÜLLER OPLADEN already supplies approx. 80% of its pipe profiling systems with automatic logistics, the figure being much lower for the rest of the world. Why invest in pipe logistics?

- Higher productivity: 30% increase in efficiency

- Less manpower: a single operator for materials handling and cutting tasks

- Less space required in the shop: pipe infeed equipment is positioned outside

- Reduced risk of accidents: no need for crane operations or pipe handling

- Less noise: no pipe parts dropping out of the machine

- Higher quality: to go easy on the material, good parts and offcuts are handled with care.

The benefits of machines with logistics in detail

The pipe profiling machine with pipe logistics permits highly efficient pipe cutting with just a single machine operator, who does not have to wait for a crane for loading or unloading.

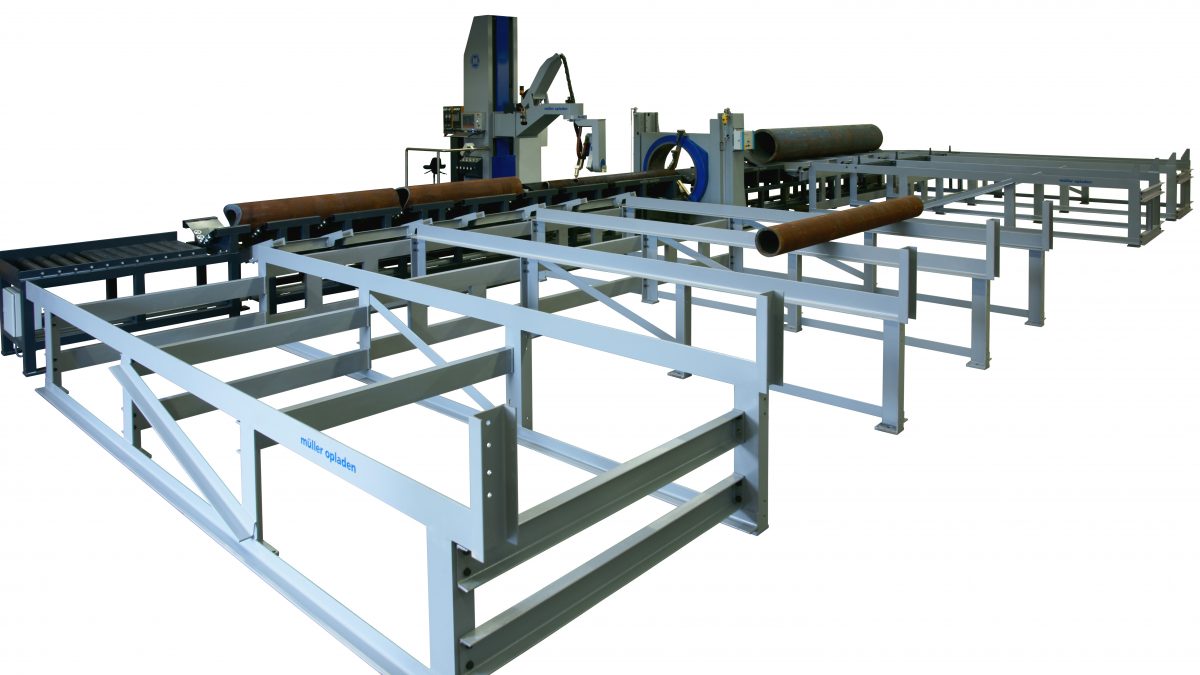

In many cases, the pipe support table and infeed conveyor are positioned outside the actual production shop. The pipes are stored out there and can then be loaded onto the pipe support table by forklift or external crane independently of the machine and its operator. This saves space and streamlines work processes.

The machine operator inside can load a pipe onto the infeed conveyor at the push of a button and then drive the pipe through an opening with a roller shutter onto the machine’s cutting conveyor. This process is many times faster than loading by crane onto a normal machine. The cutting process on the pipe profiling machine then runs fully automatically, as the operator does not have to pause the process between individual cuts, e.g. to reposition the pipe carriage or to clear away cut parts. This makes the cutting process many times faster.

Once the complete pipe has been cut, the operator unloads it from the machine at the push of a button. This can be done either laterally by ejector arms onto a pipe table next to the machine’s cutting conveyor or lengthwise onto an outfeed conveyor as an extension of the cutting conveyor. This process is also many times shorter than the usual unloading by crane.

Even if a stand-alone pipe profiling machine is efficiently supported by an indoor crane, the productivity of a machine with pipe logistics is around 30% higher. This offers customers much better efficiency. Existing systems can also be retrofitted with logistics. Just give us a call!