MO Heavy-Duty machines for 3D cutting large diameter pipes, boilers, pressure vessels, heat exchangers and tanks

For round pipes and dished ends up to 4,064 mm(160") in diameter and 30 metric tons in workpiece weight

The MO Heavy-Duty series comprises machines for round pipes and/or dished ends with a maximum diameter of up to 4,064 mm (160") and up to a pipe weight of 40 metric tons. The technology is based on that of the MO Classic series. Owing to the large workpiece dimensions and weights, the machines of this series have an extremely solid design. The machines are all equipped with 6 CNC-controlled axes.

Detailed information can be supplied on request.

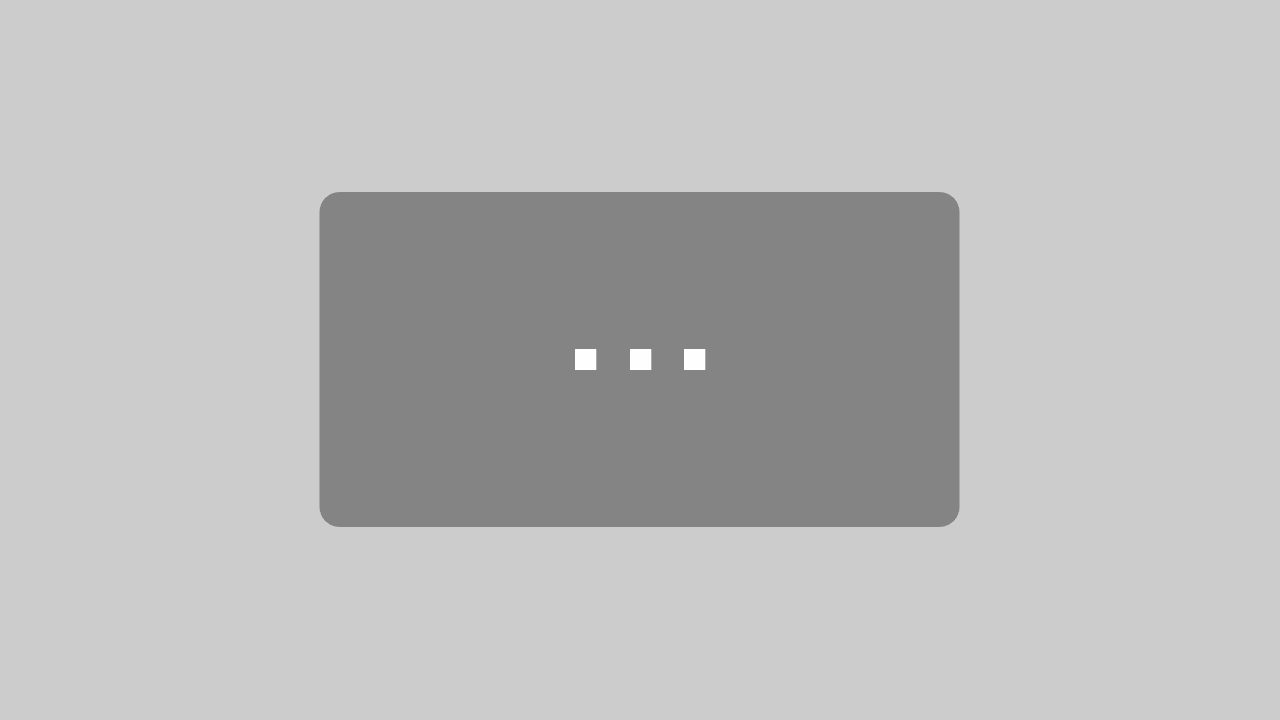

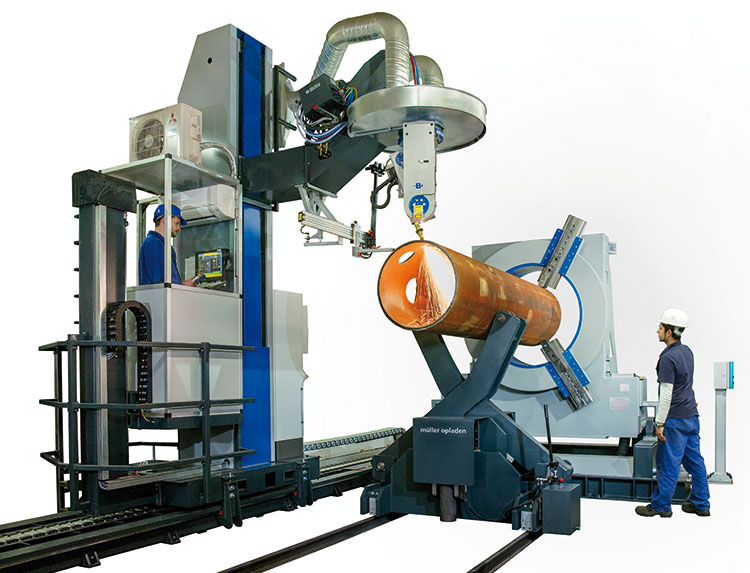

MO Heavy-Duty 4000/6

with 6 CNC axes for round pipes and dished ends with a maximum diameter of 4,064 mm (160") inclusive of Hypertherm HPR 400 plasma cutting system, oxy-fuel cutting system, height-adjustable operator stand, tilting chuck and hydraulic scissor-type pipe carriages

| Technical information / Machine series: |

MO Heavy-Duty 2000 |

MO Heavy-Duty 2500 |

MO Heavy-Duty 3000 |

MO Heavy-Duty 4000 |

|---|---|---|---|---|

| Weight of standard machine in kg: | 18.000 | 22.000 | 24.000 | 28.000 |

| Number of CNC axes: | 6 | 6 | 6 | 6 |

| Max. workpiece weight in kg: | 40.000 | 40.000 | 40.000 | 40.000 |

| Min. - max. clampable round pipe diameter in mm: | 200 - 2.032 (80") | 200 - 2.540 (100") | 200 - 3.048 (120") | 200 - 4.064 (160") |

| Max. size of chuck opening in mm: | 950 | 1.200 | 1.200 | 1.500 |

| Min. - max. clampable square & rectangular pipes dimension in mm: | - | - | - | - |

| Min. - max. clampable beams width in mm: | - | - | - | - |

| Min. - max. clampable diameter for dished ends in mm: | 400 - 2.032 | 400 - 2.540 | 400 - 3.048 | 400 - 4.064 |

| Min. - max. cuttable work- piece length in mm: | 300 - 24.000 | 300 - 24.000 | 300 - 24.000 | 300 - 24.000 |

| Min. - max. wall thickness in mm for cutting with oxy-fuel /plasma in mm: | 5-180 / 1-80 |

5-180 / 1-80 |

5-180 / 1-80 |

5-180 / 1-80 |

| Max. torch angle in °: | +/- 70 / 45 | +/- 70 / 45 | +/- 70 / 45 | +/- 70 / 45 |

Contact us for your pipe profile cutting enquiry on mail@mueller-opladen.de