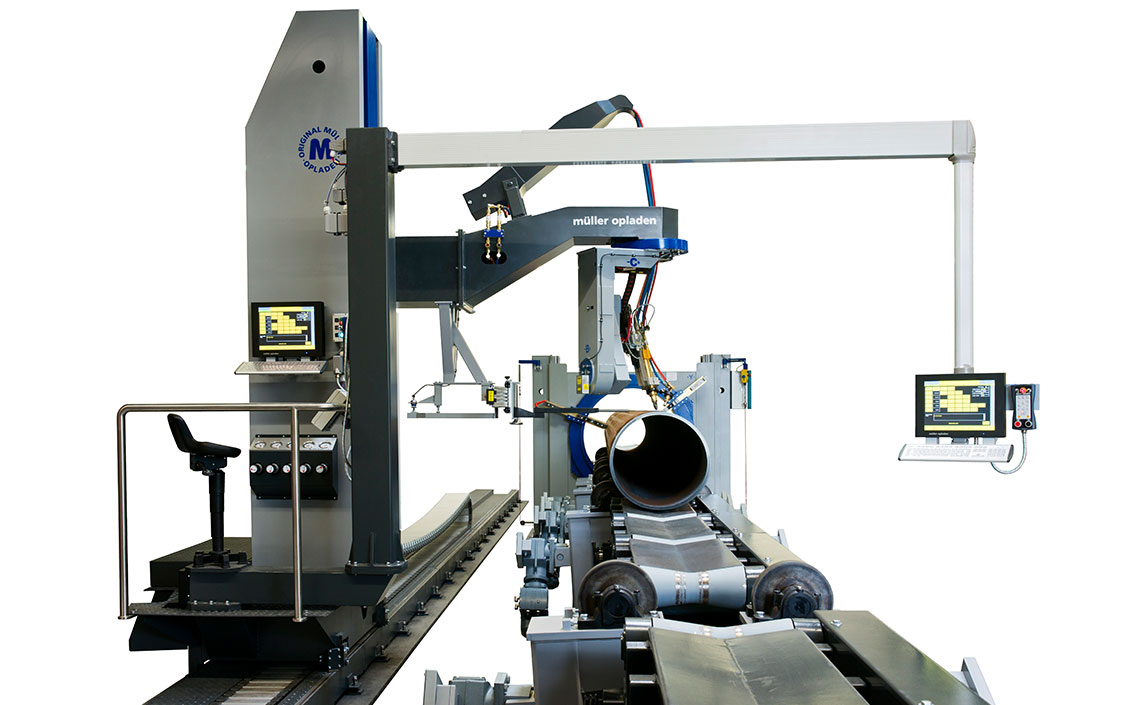

The MO Classic stationary 3D pipe cutting machine is a versatile and highly accurate profile cutting machine

For round pipes up to 2,032 mm (80") in diameter and weight up to 30 metric tons

The MO Classic series covers our classical machines primarily for round pipes with a maximum diameter of up to 2,032 mm (80") and up to a pipe weight of 30 tons. We offer this machines series in different machine models for different diameter ranges. This series is also suitable for square & rectangular pipes optionally. The maximum dimensions for square & rectangular pipes can be seen in the table of technical data.

Thanks to numerous technical optional extras, these technologically complex machines can be individually adapted to customer's specific needs. The various machines of the MO Classic series can be equipped with up to 7 CNC axes, standard the machine has 6 CNC axis if it is build only for round workpieces. The 7th CNC axis is necessary for cutting square & rectangular pipes.

Watch the video on this webpage to see how this 3D pipe profiler machine works in operation.

Contact us fore more information on the machine or different plasma and oxyfuel options or just a quotation.

MO Classic 1200/7 Classic

with 7 CNC axes for round pipes with a maximum diameter of 1,220 mm (48 inch) and square & rectangular pipes of 420 mm x 420 mm maximum (16" x 16") inclusive of the Kjellberg HiFocus 360i plasma cutting system, oxy-fuel cutting system, height-adjustable chuck and fixed-height pipe carriage

MO Classic 1500/6 Classic

with 6 CNC axes for round pipes with a maximum diameter of 1,524 mm (60 inch) inclusive of the Hypertherm XPR 300 plasma cutting system, oxy-fuel cutting system, stationary multi-point fume extraction system and motorized conveyors for infeed, cutting and outfeed.