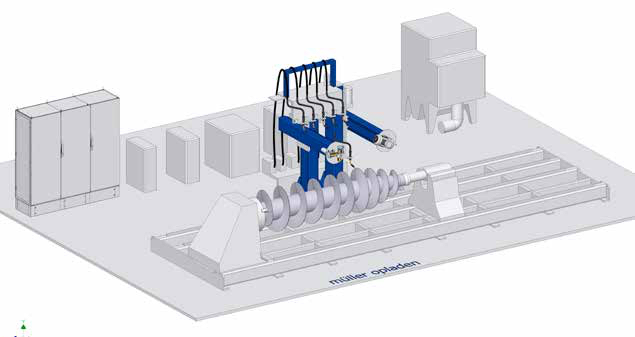

Build-up welding of high-grade surfaces

Burn-off and build-up on a single column & boom

The build-up welding units from MÜLLER OPLADEN are used for the production and repair of components such as excavator shovels, shovel segments for gas turbines and drilling heads etc. To apply new surface alloys to components, we produce a wide range of solutions based on MIG/MAG and submerged arc welding. For example, on a tailstock turning device on a column & boom, the worn surface can be burnt off with a plasma cutting head and the new alloy applied with precision by TIG welding.