MÜLLER OPLADEN saves time and money with its modular system

Individual welding units built to customer specification in a matter of weeks

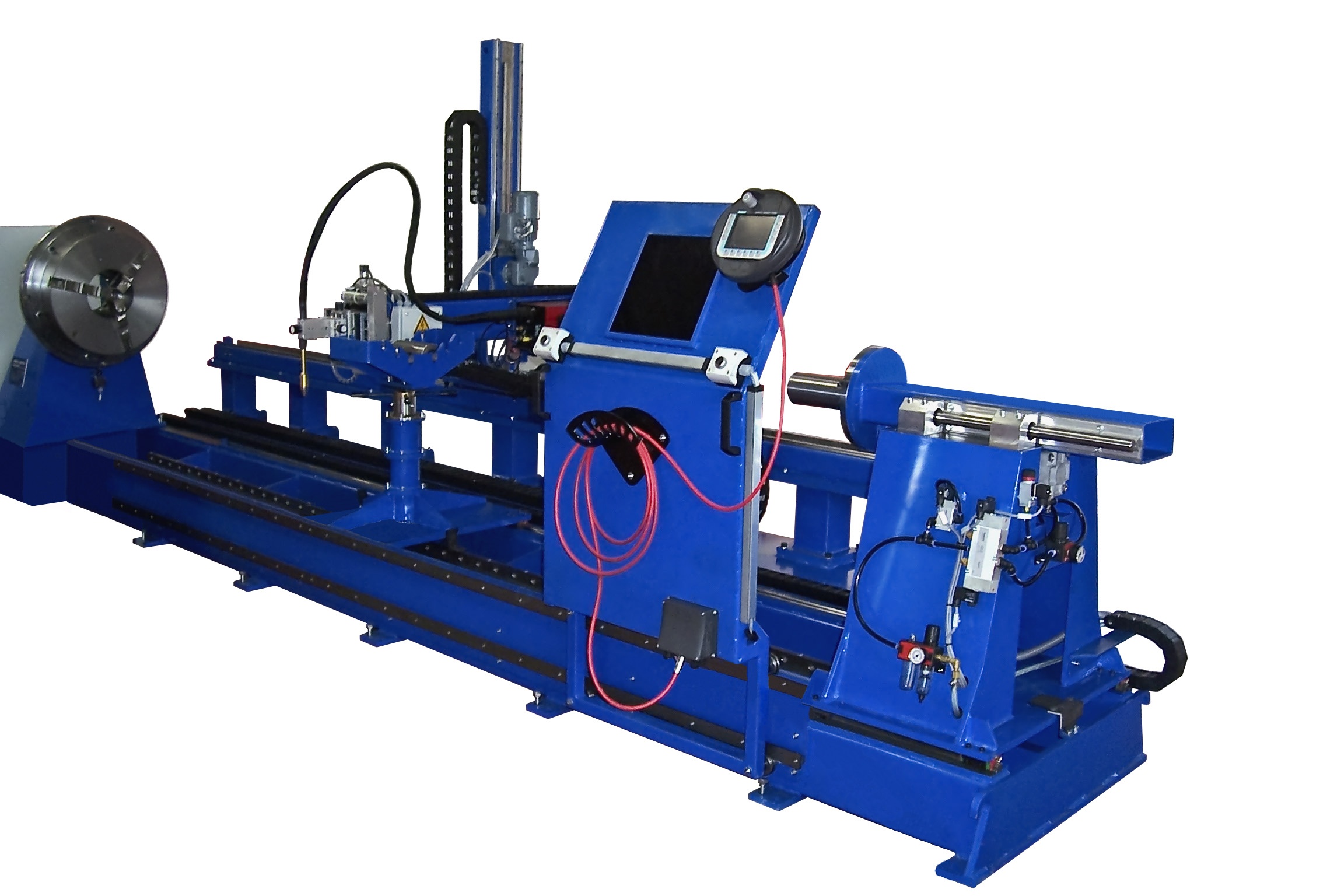

Resorting to its modular system comprising high-grade standard components, MÜLLER OPLADEN realizes customized welding units within 4 to 8 weeks. For example, we have built a circumferential seam welding unit, specially designed for welding work on compensators, and supplied it at short notice. In an automated TIG welding process, it handles cylindrical components weighing up to 100 kg with diameters of 30 to 200 mm and component lengths of up to 1,500 mm.

Standardized components, like the drive station with welding turntable MO-DT 100 HW125, a torch guide system consisting of a torch positioner MO-BST 180/100 with a pipe clamping system, and pneumatic, motorized and manual supports from the MÜLLER OPLADEN module series, permit rapid construction and delivery.