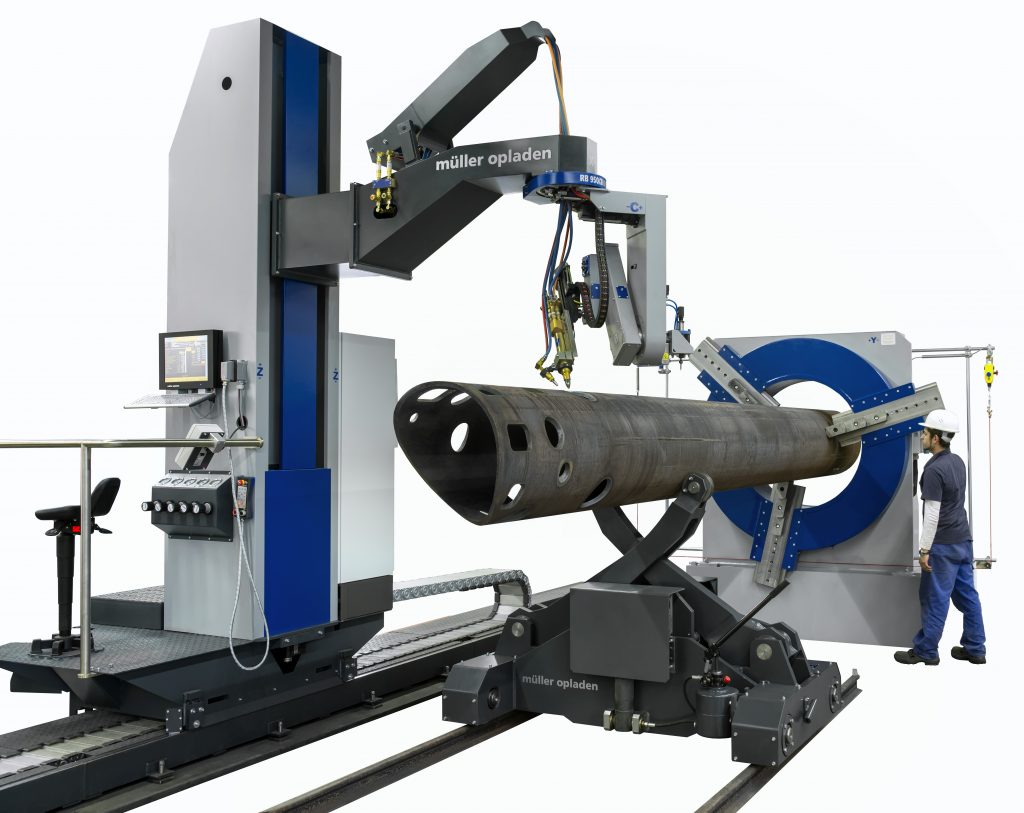

For heavy duty steel constructions like for Vessel, Heat exchangers, pressure vessels, boilers and tanks Mueller Opladen is offering solutions to do thermal 3D cutting of rat holes, slots, chamfers, saddle cuts, miter cuts, beveled holes and other 3D cuts. With our Thermal 3D cutting machine series for round workpieces the company is able to provide 3D cutting solutions for these large size workpieces, our standard machines could carry up to a maximum load of 40,000 kgs.

In these large size structures thick wall carbon steel is mostly used that is why the oxy propane cutting equipment from Mueller Opladen will suit perfectly. Mueller Opladen has standard machine solutions for oxy propane cutting for up to 4064 mm diameter but occasionally machines are offered for up to 5, 6 or even 7 meter diameter than are even more heavier. With our knowledge about 3D cutting we can offer the right suitable solutions with our engineers.

Contact us for more information on Oxy propane cutting equipment on mail@mueller-opladen.de

We have a special feature on our 3D cutting machines for round workpieces, this is the 3D vessel head cutting module . With this option we create a chuck that is used in vertical up right position when the vessel, cylinder or pipe is 3D cutted. Then this chuck is rotating the workpiece during the cutting process as well. When that cutting job is finished, that same chuck is put in horizontal than it will be used as a table to put the vessel head on from your vessel or boiler. We can 3D cut the vessel head on your oxy propane cutting equipment or plasma cutting could be used to do the 3D cutting work.

visit our website www.mueller-opladen.de for more information about our oxy propane cutting equipment for thermal 3D cutting of steel workpieces.

Contact us for more information on Vessel and Vessel head cutting solutions on mail@mueller-opladen.de and our sales team will advise you on the right machine solutions

The 3D cutting machines we manufacture at Müller Opladen for thermal cutting of steel could be equipped with oxy propane cutting, we have different oxy fuel options to choose from. The oxyfuel propane cutting is most of the time taken when there is only carbon steel to be cutted and when the wall thickness is in general above 15 mm thickness.

Mueller Opladen is the manufacturer and engineer of thermal 3D cutting machines since the 1950s worldwide the company has sold and installed many oxy fuel and plasma cutting machines for pipe fabrication but also for structural steel fabrication.

For pipe profile cutting we can equip the machine with both plasma cutting and oxyfuel propane cutting if this is required. We can cover with many different machine solutions up to 4,064 mm pipe diameter and if needed up to 40,000 kg maximum pipe weight.

Visit the overview page for all our 3D pipe cutting machines on our website, to make the right selection for your pipe fabrication work.

Our 3D oxy propane cutting machines are used in the vessel, boiler, heat exchanger and tank manufacture but also in tube and pipe fabrication activities.

Visit our website www.mueller-opladen.de we focus on high-quality german made machine that last for a very long time and besides that have a competitive edge above other because the machine is able to adapt on and deviations that are encountered during the scanning phase.

We also offer oxy propane cutting machines up to 914 mm pipe diameter and for example for 12 meter long pipe this is one of our most sold machines, we can equip this machine with a CAD-CAM software.

Contact us for further information or a quotation on mail@mueller-opladen.de