MÜLLER OPLADEN – Technically the Best Solutions Worldwide

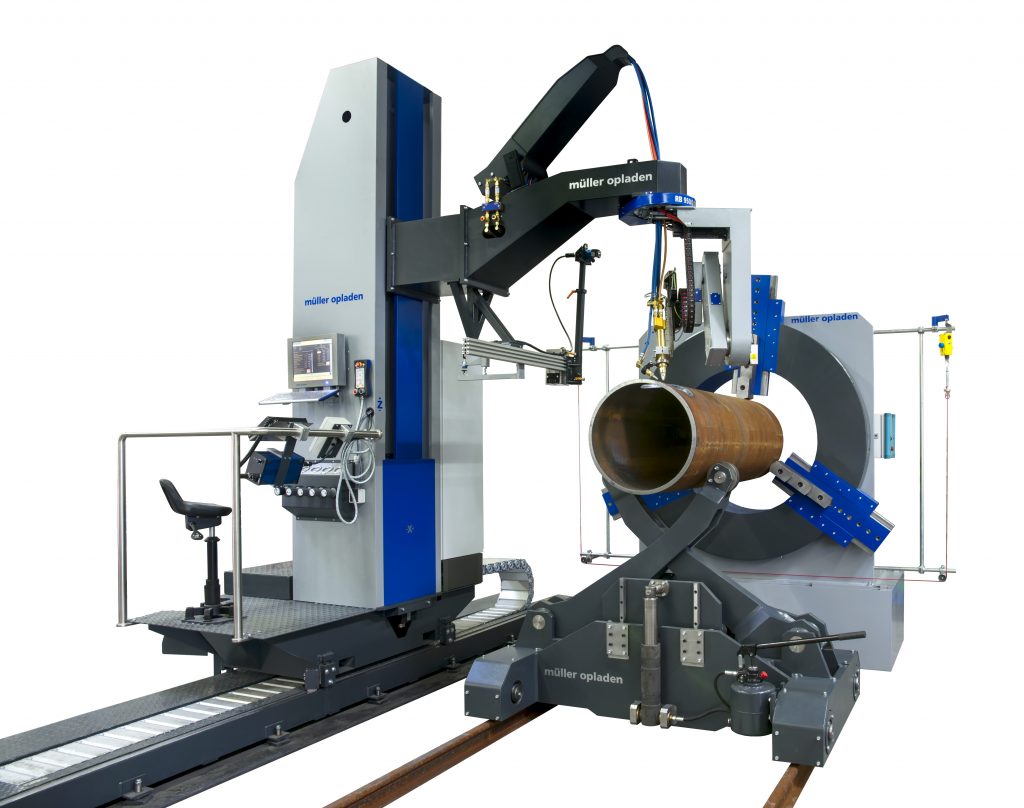

3D Pipe Profiling Machines for Efficient, Automated Production Systems

MÜLLER OPLADEN offers technically mature solutions for all aspects of modern 3D pipe processing. A thousand customers in over 70 countries worldwide therefore rely on our German-made equipment when it comes to the efficient and precise flame-cutting of steel and stainless steel pipes measuring up to 4,064 mm in diameter and up to 24 m in length and with unit weights of up to 40 metric tons.

Since the first machines were built in the 1950s, the flame-cutting machines from MÜLLER OPLADEN have been consistently further developed and will therefore stay “state of the art” in the future. From our close contacts with the market, we know the requirements of our customers and the challenges of modern production plants and of future Industry 4.0 strategies.

Entirely in line with our customers’ requirements, we build customized MÜLLER OPLADEN cutting machines with up to 7 CNC axes and using the plasma and laser thermal cutting processes in five series: MO Compact, MO Watts, MO Classic, MO Heavy Duty and MO Robo. The equipment features range from a reliable marking system to a complete enclosure and extraction system. Highly responsive sensors and modern control technology ensure that even pipes that are out-of-round (eccentric) are cut to perfection.

The extensive CAD/CAM software with profiling macros, modeling and nesting modules and SQL databases ensure super-simple programming and operation, efficient job scheduling, optimal and material-saving cuts and integration into automated production processes. MÜLLER OPLADEN also of course supplies the desired handling systems for pipe profiling machines to ensure frictionless production processes.

website www.mueller-opladen.de