US Corporation orders State of the Art Profile Cutting System

Several workstations plus logistics set standards

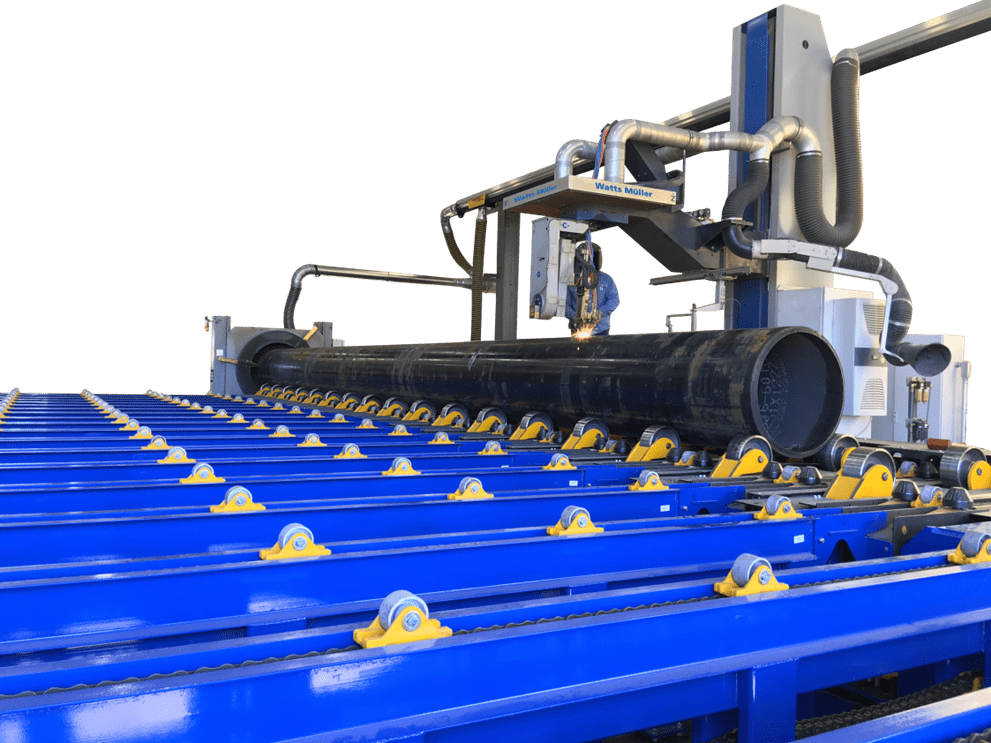

In cooperation with its affiliate Watts Mueller in Seattle, MÜLLER OPLADEN has captured a milestone contract. In its configuration of a unique processing line for pipes and dished ends with several workstations, advanced software and comprehensive handling, a US corporation is exploiting MÜLLER OPLADEN’s decades of experience from a multitude of different pipe-cutting projects and Watts Mueller’s logistics expertise.

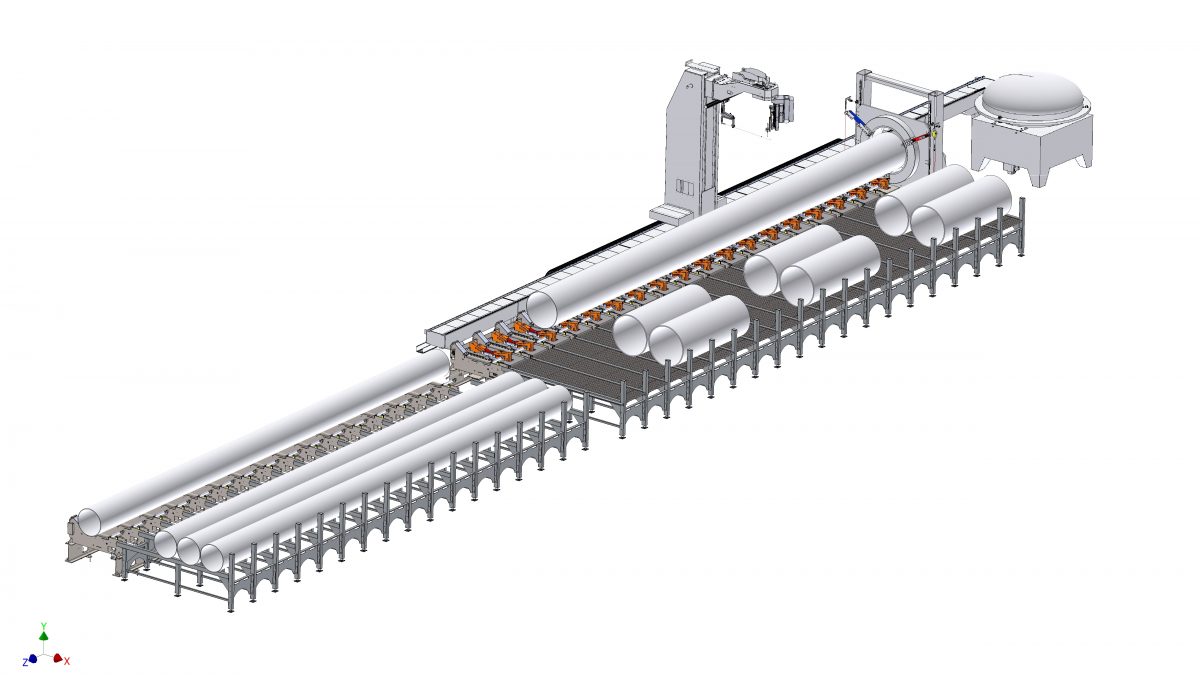

The line starts outside with a pipe-loading table and infeed conveyor that carries the pipe workpieces inside to the machine and delivers them onto the cutting conveyor where pipes up to 1500 mm in diameter are cut to perfection. After cutting, the pipes are automatically fed by the cutting conveyor onto a support table.

Integrated behind the pipe chuck is a second workstation on which dished ends can be cut fully automatically.

The customer expects extra value, superlative efficiency and top quality from the combination of German engineering and US expertise.