Metal pipe fabrication is in fact containing all work that is done in a factory or pipe shop related to metal pipes. These are activities are pipe sawing, pipe cutting, pipe welding, pipe bending and pipe profiling or pipe beveling.

Visit the Mueller Opladen website for CNC pipe profiling machines and their oxy fuel and plasma cutting process on www.mueller-opladen.de

The 3D pipe profile cutting machines cut with plasma or oxyfuel the contours and shapes out of the pipe, with this flame cutting process you can cut miter cuts, slots, holes, straight cuts and bevels on pipes. Go to this website of the MO-Compact to see the video for a good understanding and on that same website of that pipe cutting machine you will find more technical information and videos.

Our 3D pipe profiling machine suits perfectly in any kind of pipe fabrication factory when there is a certain volume of profile cuts to be done per month. Contact us for quotations on mail@mueller-opladen.de

Within straight cutting or sawing of metal pipes there are many different methods in the world that all have different approaches in order to separate the pipe. Bandsaws, flying saws, orbital sawing machines you name it many different options. For cutting of pipe you also have different solutions but there are to be divided into cold and hot cutting methods. Cold cutting could be for example with a cutting bit.

Examples of hot cutting process are related to thermal cutting process such with oxy-fuel, plasma cutting or high definition plasma cutting. That being said within fabrication of steel pipe there are also different ways to connect pipe segments to each other, for example with flanges or with different pipe welding process such as Electrode, GTAW, GMAW or SAW welding processes.

Within pipe fabrication we as Mueller Opladen can offer you both automated welding solutions for pipe spool fabrication but also are we sell world-wide stationary machines for pipe profile cutting and square profile profile cutting.

If you have a special cutting or profiling request related to steel fabrication contact us by sending us an email on mail@mueller-opladen.de

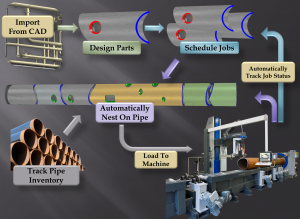

In factories where pipe fabrication is done, in many cases people are looking in to automating the factory if a certain output is required otherwise all pipe fabrication activities are manually and very time consuming.

visit the website of Mueller Opladen for our 3D pipe profile cutting machines and our automated welding machines.

Automated pipe shops or so-called pipe fabrication factories could have automated conveyors that the pipes are being transported automatically from the sawing station to the beveling station and after that to the pipe profiling station for hole cutting for pipe branches and maybe saddle cutting at the end of the pipe.

A next station could be after the pipe profiling station is in most cases the automate pipe welding station.

The machines we offer for pipe spool fabrication are our stationary machines for 3D pipe profiling and our automated machine solutions for pipe to fitting welding. Visit our the website of Mueller Opladen for more information on the machine for cutting and welding activities related to pipes.

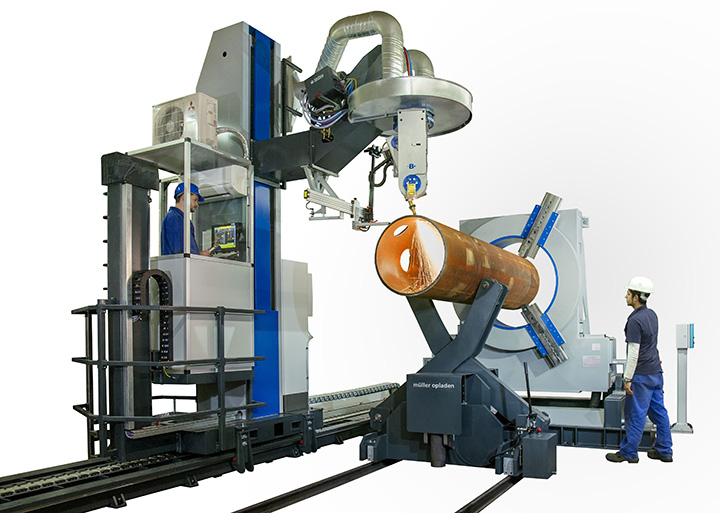

Our CNC pipe profile cutting machines for both steel pipe and tube are the best high-quality and advanced machines in the world, go to the MO-Classic series website to see a video clip of one our most versatile machine for pipe cutting and profiling with 3D shapes and contours.

The MO-Classic machine is offering you a 7 axis CNC machine, no were like any other pipe profile machine manufacturer in the world. This machine has the innovative software to upload, edit and alter you technical CAD files in the MOCAM software if all is ready it could be sent to the cutting program after that you could easily do the cutting according to the CAD file.

If you desire a quotation on one of our cnc pipe profilers contact us by email on mail@mueller-opladen.de and we will reply you shortly.

Mueller Opladen is since the 1950s manufacturing multiple axis CNC machines that do 3D pipe profile cutting , visit the MO-Compact website to see different machine models that can to pipe profile cutting up to 36 inch for your pipe spool fabrication activities

For your pipe fabrication this MO-Compact machine is very useful because it allows you to cut in your pipes miter, saddle, slots and holes. Go to the webpage with different cutting profiles to see if the machine meets your requirement for pipe profiling.

Mueller Opladen has built a fast experience in providing automated pipe spool welding solutions in fully automated pipe spool factories or so-called automated pipe shops. In a couple of cases Mueller Opladen installed it’s automatically infeed, welding and out feeding pipe to slip-on-flange welding machine that is covering pipe and flange diameters from 1” to 18” .

World-wide there are very little manufacturers that can even get close to the level of technically expertise in this field. The highly advanced machine functions that Mueller Opladen offers in it’s equipment for pipe to flange welding machine is top of the bill.

With more than 40 CNC axis the pipe to flange welding machine is doing the pipe spool fabrication of one up to 6 meter long pipe with on both ends one slip-on-flange. The end customer could even decide if they want automatically in feeding and out feeding of the pipe into the machine.

Also, are these machines like all other machines at Mueller Opladen are offering reliability, constant quality and high-quality level of technique and innovation. Visit the website of the pipe to slip-on-flange-welding machine to see if this machine could fit in your pipe spool fabrication activities

If you have a special request for automated pipe spool welding contact us on mail@mueller-opladen.de

The stationary pipe cutter machines that we manufacture since the 1950s are very versatile 3D pipe coping machines for any kind of steel pipe work fabrication that you could imagine.

On the machine and cutting head of the MO-Compact for example are 6 axis that are controlled over the CNC controls and software of the machine. These 6 axis is our standard, all these axis have a real important function, there are horizontal and vertical axis on two columns, than there is a rotating clamping axis and we have 3 axis on the cutting head.

One of those axis on the cutting head is for adapting on out of round pipes, first the pipe will be scanned by a mechanical tracer or a laser system to tell the software where eccentricity and ovality are in the pipe and the software than adapts with it’s machine settings.

The technique is that the 6th axis enables you with your pipe work fabrication to pull up the axis while cutting under exactly the same angle which means that you still have an accurate end result according to the CAD drawing.

Visit the website of the MO-Compact for more information and videos.